An enormous amount of productivity is lost because the correct oil or grease is not properly installed at the right time. Lubrication is a critical responsibility, but in many organizations effective techniques and the technicians who know and do them get little respect. Building the role of lubrication experts -- your "men in black" -- is a relatively low-cost way to materially improve reliability.

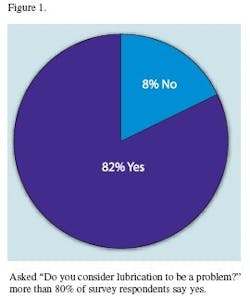

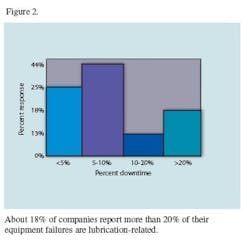

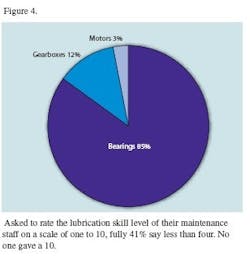

Studies have shown that 70% to 85% of equipment failures are self-induced, meaning that maintenance practices and processes are directly responsible for the failures. A recent survey I conducted online shows that poor lubrication practices represent about 40% of maintenance-related self-induced failures. In the same study, more than 80% of respondents indicated they consider lubrication to be a significant problem in their operation.

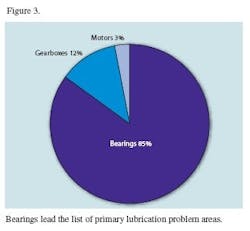

Lubrication plays a role in the operation of most equipment -- gear reducers, electric motors, chain drives, air compressors, bearings and more -- so its obvious that doing it properly is key to the success of capital-intensive companies.

One of the main reasons companies struggle with lubrication effectiveness is they over-rely on standard original equipment manufacturer (OEM) recommendations. Instead, lubrication activities should be driven by asset health and the true lubrication needs of the asset. The combination of the right lubrication activities and proper practices creates a significant opportunity to improve plant reliability.

Big, bad and ugly

More than 200 maintenance professionals participated in the August, 2005 survey on lubrication and its impact on reliability. The results may shock you, or they may simply validate what you are seeing in your operation. Its clear that although some companies are doing things right when it comes to lubrication, most are not.

Do you consider lubrication to be a problem? Responses to this first question clearly show the significance of lubrication with more than 80% saying its a problem in their operation (Figure 1).

Make lube expertise a specialty

The results of the survey point to three conclusions. First, training is an issue. Most companies either do not look at lubrication training as important or they use what I call "check the box" lubrication training: if asked, "Do you train your people in lubrication?" they answer yes, but the training is not focused enough to change behavior.

Second, lubrication procedures have either not been developed or are not followed. You can have the best lubrication procedures in the world but if no one follows them, theyre useless. Management must ensure proper procedures are written, then ensure they are followed.

Finally, it seems that organizations do not understand the relationships between lubrication and reliability. Many failures attributed to normal wear or faulty components are actually caused by poor lubrication practices (Table 1).

|

Problem |

Root cause |

|

Bearing failure due to contamination of grease with dirt, dust or silica |

Failure to wipe grease fitting or the end of the grease gun nozzle clean |

|

Bearing failure due to contamination of grease by dirt, dust or silica |

Seal not holding due to over-lubrication |

|

Bearing failure due to lubricant not providing barrier to prevent metal-to-metal contact |

Wrong grease/oil or heat reduced viscosity due to temperature rise beyond range of lubricant |

Gear reducers

|

Problem |

Root cause |

|

Failed bearings and damaged gear teeth due to contamination causing interference between gears thus overloading bearings |

Gear oil added to gearbox through a dirty funnel or dirty container or bucket |

|

Failed bearings due to contamination of lubricant with dirt, dust or silica |

Seal leaking due to over-pressurization of gearbox caused by blocked air intake on housing |

Electric motors

|

Problem |

Root cause |

|

Bearing failure due to contamination of the grease with dirt, dust or silica |

Failure to wipe grease fitting or the end of the grease gun nozzle clean |

|

Bearing failure due to contamination of the grease with dirt, dust or silica |

Seal not holding due to over-lubrication |

|

Windings failed because of grease buildup inside the motor |

Relief plug not removed before introducing grease into zerk fitting |

|

Windings failed because of grease buildup inside the motor |

Sealed bearings -- grease cannot enter the bearing |

Get the job done

So implementing effective lubrication practices is important. The necessary steps depend on where you stand. First, review the current lubrication practices. If time-based preventive maintenance procedures are followed, consider whether or not the reliability of the equipment can be monitored based on condition instead of time.

Figure 5 illustrates the typical room for improvement. It validates our survey in showing that reactive maintenance is the norm: too little, too late. A "best in class" organization will monitor bearing condition based on oil sampling, heat gain, vibration analysis, current draw, ultrasonic and other predictive technologies.

An effective monitoring program will manage condition data with alarms set in a CMMS/EAM to tell maintenance when action is required. There are software programs sold on the market today that do just that.

There will always be lubrication practices that require time-based PMs, but consider implementing condition-based PMs. I am not recommending you run out and implement a condition-monitoring program, but think about how you might improve the way you lubricate your equipment.

When you have considered and, if necessary, modified your lubrication practices, implement an effective training and monitoring program. The outline of an example program is given in the sidebar, "Hit list."

Track performance of your lubrication program through agreed-upon metrics. Possibilities include MTBF (root causes of failures will have to be determined to identify lubrication failures), production losses, maintenance costs associated with each problem piece of equipment, and replacement parts costs.

Start with a baseline of the metrics before you implement the program, and measure afterwards on a weekly basis. Trend the results and post without comment for four weeks. After four weeks, allow your maintenance staff to comment on the results. See what is working and what is not, and understand what is a process problem and not a people problem. People problems can be solved through training and enforcement of the standard.

Keep everyone involved and interested with a Top Five list of lubrication failures: post the top five problems of equipment that has failed due to lubrication issues. Post charts of the metrics, and have the maintenance staff identify on them what actions were taken to correct problems.

In short, preventing failures via proper lubrication depends on two things: defining and documenting procedures with specifications, and having the discipline to follow those procedures. An educated staff is more able to understand the reasoning behind the procedures, and thus more likely to be proactive in following them. Create and support expert "men in black" to rid your plant of lubrication problems.