For many of us, January is a time of new beginnings and fresh resolutions. One resolution that plant managers should make this year is to pay more attention to the condition of their roofs particularly metal roofs. Winter and the spring thaw that will soon follow causes metal roofs to expand and contract as the temperature changes. The movement puts pressure on the roof panels and, over time, can enlarge the screw or fastener holes in the roof panels. These holes quickly become apparent during the next rainy season, when rain leaks on the plant floor. So while the roof may appear to be in good shape at the moment, a prudent plant manager will make a resolution now to prepare for a roof failure later.

Step one: Understand metal roofs

Metal buildings are popular because they are a relatively inexpensive and quick-to-erect alternative to other types of buildings, such as bricks and mortar or hard-sided buildings. However, one downside to this type of construction is the potential for roof-related problems.

There are two types of metal roofing systems. Through fastened roofing systems feature fasteners or screws installed through roll-formed roof panels into the purlins or the roof's structural supports as well as through end laps and side seams. Standing seam roofs have machine-roll-locked seams and are secured to the purlins with hidden clips.

Both systems harbor potential problem areas where leaks commonly occur. One is at the side and end laps of the metal panels, where the original butyl tape seals often age and fail. Another is where the fasteners penetrate the panels, as mentioned above. Finally, many metal roofs have panels with lapped joints like a shingled roof, and the caulk or sealant at these locations eventually deteriorates. This problem is prevalent with lower-sloped roofs often found atop manufacturing plants.

Step two: Find the cause of the leak

If a metal roof leaks, the first thing to do is identify the cause and determine if it can be repaired. For instance, if the fasteners are backing out, larger diameter screws might be the solution.

Usually the problem is not so easily fixed, and the roof needs to be recovered or replaced. Before deciding what to do, consider several important factors. For instance, identify what caused the roof problem and how it can be avoided in the future. If it's desirable to add more insulation to the roof or install a new roof, ensure the building structure can support the additional weight. Review the building code and insurance requirements for a new roofing system.

To cost-justify the decision to upper management, be sure to point out that factors other than the roof's initial cost determine the ROI.

Step 3: Know your options

The decision to recover or replace the roof presents you with several options to consider.

Metal roof recover:

This involves either removing the existing metal roof and replacing it with a new one, or, if the building can support the additional weight, installing a new metal roof directly over the existing surface. The main advantage to the recover option is that the new roof matches the building's original design. However, over time, the new metal roof may suffer the same problems as the previous one. And at up to $10 per square foot (depending on the number and type or roof penetrations) it's also more expensive than the alternatives.Coatings and liquid-applied systems:

Installing elastomeric coatings involves cleaning the roof thoroughly, replacing damaged and severely rusted panels, and treating less-rusted panels with a coat of primer. Exposed fasteners and flashings are sealed and new reinforcing fabrics and flashing compounds applied at the side laps. The roofing compound is then roller- or spray-applied in numerous coats to build the desired thickness.This option can be relatively inexpensive, depending on the number of coats applied, and is good at stopping corrosion and leaks. Another benefit is that elastomeric roof coatings are usually white, which reflects the sun's rays and keeps the plant cooler.

A disadvantage is that many coatings aren't flexible enough to accommodate expansion and contraction, which means they can crack and leak at joints and seal areas. Such leaks may require additional coating and flashing work. It's not unusual for a metal roof to require re-coating or joint and fastener re-sealing every five years or so. The cost of reapplying a coating adds up quickly over a 15- to 20-year period.

For this option, ensure the existing metal panels are prepared properly and the coating is applied during mild weather conditions usually clear and dry with a minimum temperature of 50F, a situation that's not common for most of the United States in January, February and March.

Polyurethane foam recover:

This option is spray-applied in a manner similar to a coating. After prepping and treating the existing metal roof for surface corrosion, applying several layers of insulating foam achieves a total thickness of 1in. or more. A surface coating is then applied over the insulating foam to protect it from solar damage.This option offers several benefits. It typically adds significant R-value to the roof's insulation. It doesn't require reinforcing fabric at the laps and fasteners. Its major disadvantage is that it makes the roof more rigid, which doesn't accommodate the building's normal expansion and contraction. The foam's long-term weatherability is controlled by the quality of the thin surface coating.

Single-ply recover:

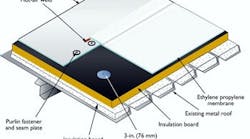

Single-ply membranes, such as hot-air-welded thermoplastic polyolefin (TPO), also can be installed directly over an existing metal roof (see Figure 1). Preparatory measures include replacing damaged metal panels and installing insulation strips between the ribs or flutes of the existing roof to enhance the roof's overall R-value and to provide a solid substrate for the single-ply roofing system. Next, installing a second layer of insulation provides a uniform, solid substrate for the roofing system.The single-ply membrane is then rolled over the substrate and either mechanically fastened to the purlins or fully adhered directly to the insulation. The seams are welded together using hot air. Because metal roofs are usually made of relatively light-gauge panels, special fasteners must be used on mechanically fastened systems to secure them. Ensure the fastener type and spacing meets applicable Factory Mutual or local building code requirements, as well as the manufacturer's pull-out resistance requirements for wind design.

There are numerous advantages to a single-ply recover. One is that single-ply membranes are usually available in light or white colors, which, like coatings, reflect the sun's rays and thereby keep the building cooler. Another is that TPO membrane is flexible and can accommodate normal expansion and contraction easily. In addition, the cost of a single-ply recover includes the additional insulation and usually is highly competitive with a coating system making it an attractive option. Plus, many single-ply systems have a 20-year warranty, and don't have the maintenance needs typical of coatings.

The drawback is that it's more expensive than some alternatives, although the other choices might cost more in the long term. In addition, installation requires a qualified, experienced contractor who is familiar with hot-air welding and is knowledgeable about single-ply systems.

Figure 1.

In a single-ply recover, the membrane may be mechanically fastened (above) or adhered directly to the insulation.Step 4: Prepare your case

After researching the options, obtain the necessary funding to invest in your decision. To cost-justify the decision to upper management, be sure to point out that factors other than the roof's initial cost determine the ROI. For instance, light-color roofs reflect as much as 80% of sunlight, thereby minimizing air-conditioning costs. By contrast, according to the Environmental Protection Agency, black roofs can be as much as 100F hotter than a reflective white roofing surface. Also mention if the roofing option adds to the roof's R-value and the associated long-term energy savings.

Finally, discuss the life cycle cost of the roofing option and whether most of the cost is up-front or hidden, such as having to reapply a coating periodically to the surface or to the fasteners. Other questions of interest include how long is the roof expected to last and the warranty that comes with it.

By doing the research and evaluating the options now, before the roof is leaking, you'll be able to make an educated, calm, cost-effective decision when the time does arise to deal with a failing metal roof. In the end, that's one resolution you'll be glad you kept.

Steve Moskowitz is vice president of technical and warranty services for Stevens Roofing Systems in Holyoke, Mass. E-mail him at [email protected] or call him at (800) 621-7663.