Hydraulic fluid performance requirements are developed from failures and performance standards. To understand the requirements, identify causes of downtime, parts replacement and labor costs. Then, identify the standards to be used as basic performance levels. Hydraulic fluid has several functions, all of which can be affected by the following problems:

|

View related content at PlantServices.com |

- Leaking seals —one drop every 10 seconds equals 70 gal. per year. A drop every second represents 420 gal. annually. Leaking seals can also contribute to low oil levels that cause erratic operation, pump cavitation, high operating temperature and contaminant entry.

- Solid contamination — airborne dirt, dust and fibers enter through leaking seals, vents and breathers and during oil addition or change-out. Solid contaminants between five and 15 microns are the major source of pump failure. The hydraulic system filter that removes only particles larger than 10 microns allows the smaller particles to pass through. A worn vane pump rotor can’t be rebuilt if the vane slots are worn more than 0.02 in.

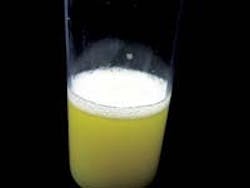

- Moisture contamination — whether from high relative humidity or through leaking seals, moisture can condense and form water droplets that saturate the fluid (Figure 1). The result is accelerated fluid oxidation, foaming, overheating, rust and corrosion.

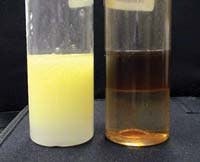

- Foaming and aeration — normal operation can mix air and oil (Figure 2). Foam leads to non-lubricated hot spots, which contribute to excessive pump cavitation and wear. Pump cavitation can develop into erratic operation, which can lengthen production times and contribute to part quality issues.

- Fluid oxidation — accelerated contact with yellow metals, which are common in hydraulic systems, every 15°F increase in operating temperature beyond 150°F doubles the oxidation rate and shortens fluid life by 50%. Oxidation can thicken the fluid and produce acids, sludge, varnish and gum. Valves start sticking and deposits build up on sensors, pumps and bearings (Figure 3). Pressure and temperature readings become inaccurate, components wear and lines plug.

Water causes corrosion

Figures courtesy of NCH Corp.

About the Author

Michael Holloway

Michael Holloway

Michael D. Holloway is President of 5th Order Industry which provides training, failure analysis, and designed experiments. He has 40 years' experience in industry starting with research and product development for Olin Chemical and WR Grace, Rohm & Haas, GE Plastics, and reliability engineering and analysis for NCH, ALS, and SGS. He is a subject matter expert in Tribology, oil and failure analysis, reliability engineering, and designed experiments for science and engineering. He holds 16 professional certifications, a patent, a MS Polymer Engineering, BS Chemistry, BA Philosophy, authored 12 books, contributed to several others, cited in over 1000 manuscripts and several hundred master’s theses and doctoral dissertations.