Resurfacing a floor is for more than just looks

I recently visited a showcase facility just two years after a complete renovation. The grounds are impeccable, the offices lean but lovely, the manufacturing and warehouse areas brightly lit and spotless. But the materials the facility handles are heavy, and even at its young age, the floor is hurting, especially in high-traffic forklift areas around scales and storage. The coating shows wear and spalling, and the almost-new exposed concrete not only looks bad, but is being damaged by exposure to hard wheels and pallet nails.

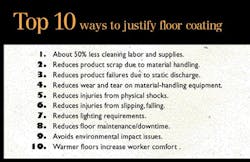

There are many reasons to coat and maintain an industrial floor. It can increase sales, improve product quality, improve worker comfort and safety, and reduce maintenance costs in both the short and long run. Though some consider floor protection frivolous, you can calculate the payback it's likely to be shorter than you'd expect.

And of course, it looks fabulous.

When all you need is love

Excessive product scrap provided motivation and justification for floor resurfacing at the Indalex aluminum extrusion plant in Elkhart, Ind. The combination of high temperatures, heavy forklift traffic, and impacts from dropping 2,000- to 8,000-lb. aluminum dies made the floors a rough ride for finished parts. "We were running at 8% scrap, and 1% of that was directly caused by dents and banging from floor problems problems that translated to $280,000 off of my bottom line," says Pat Meyers, owner.

"Regular epoxies did not hold up," says Jeff Berlew, president, Northern Industrial Flooring, Orland, Ind. (www.locl.net/homes/northern). "The first attempt wore too fast, leaving chewed-up floors with four- to five-in. holes in the concrete. The second showed failure after just two months."

"When you need a plant running around the clock like we do," Meyers says, "you can't have your lines shutting down again and again. Despite great warranties, I can't afford to honor them. It is frustrating to pay $80,000 for a floor that holds up for less than two years. Northern Industrial recommended reinforced epoxy, which has withstood the conditions at Indalex." Berlew says, "The reinforced epoxy resists abrasion and shock even skid nails won't scratch it. It just does not fail."

Paying more up front to reduce scrap and lifecycle cost made obvious sense. "There's a little bit of a cost premium, but not in the big picture," Berlew says. "You only do the preparation and labor once."

And, of course, if floor damage leads to shutting down an area for repair, you have to consider the cost of lost production. "In high-traffic, critical areas," Jewell says, "resurfacing can be justified based on reducing repairs to concrete."

You can work it out

Floor coatings range from thin to thick, epoxy to acrylic, water-based or solvent-borne, in myriad combinations of aggregates and layers. Each possible combination of materials and application techniques results in a unique compromise of properties and cost. There are few absolutes, but there are several interesting trends in coating materials you should know before discussing your requirements with your favorite floor professional.

One significant trend is the movement toward thicker coatings, also called resurfacers or toppings. One reason is that industrial floors in the predominantly brownfield United States tend to have the pitting, holes and other damage these coatings can fill. Another is increased recognition of lifecycle cost.

"People who were doing coatings are doing resurfacers," Beck says. With proper maintenance cleaning and touch-ups a 15- to 20-mil coating might last three to four years, he says. Resurfacers, which run from 60 mils up to 3/16 or 1/4 in., will last 15 to 20 years with the same kind of care. "They cost maybe $3 to $4 a square foot where coatings cost $1 to $1.50, but the lifecycle cost is lower. People are switching because they know what it costs to shut down."

Shutdown costs are always a consideration. Curing or drying speed can make or break a floor finishing plan, and there are now fast-curing acrylics and UV-cure coatings. "With fast-curing acrylics, within an hour of your final coat you can have a finished floor," Paggioli says.

"With UV drying, you run a light over it and bingo, it's dry," says Ken Hughes, vice president, marketing, Garland Floor Co. (www.garlandfloor.com). "Today it's not as durable, but it's improving all the time. UV-cure coatings are subject to yellowing as time passes." "All coatings yellow, some more than others," Hughes adds. "We're working on a coating that won't yellow. People want decorative floors, so that's important."

Methyl methacrylate cures quickly under damp and cold conditions, which makes it attractive for new construction and instances when floor coating comes late in the schedule, and you want to get the investment up and running. But these coatings have a strong odor. "In an operating plant, it has to be done off-hours or on a light shift," Jewell says. "Urethanes are not as fast but don't have the odor. In the past several years, we've seen urethanes take a stronger position with good resistance to food acids and thermal shock."

Concerns about VOCs and emissions have led to waterborne coatings that rival the performance of solvent-based stalwarts, but, according to Hughes, water is still not as good as solvent.

Here, there, everywhere

Different resin systems can be combined in layers to suit the installation conditions, as well as the ultimate application. "I like to finish with aliphatic polyurethane," Cline says. "Epoxies bond better to the concrete, but poly gives better wear, holds its color well, has a nice sheen, and we can put in non-slip additives."

But you don't have to go far to find fans of the tried-and-true. "Epoxy is still king," Jewell says. "For durability, cost and ease of application, it's a good value, and the others cost more. As I see it, it will hold that position."

If we're giving you the impression that coating chemistries are complex, decisions aren't straightforward, and the choices depend on your exact circumstances, we've done our job. It's worth evaluating your requirements and working through your options to get floors that really fit the needs of different plant areas. "Epoxy versus acrylic versus urethane, resurfacers versus coatings what are you using it for?" Paggioli says. "Traffic, chemicals, slip-resistance, smoothness and cleanliness you need to install the right coating for the environment. Then, of course, there's schedule and cost."

"A concrete floor tends to be the same everywhere," Beck says. "With the coating technology now available texturing, safety, ESD you're able to take a section and make it uniquely suitable for its purpose. The floor can be adapted to the manufacturing, not vice-versa."