In the beginning, there was chaos. Workers were inefficient, managers ineffective, machines unreliable and materials inconsistent. Thus, senior management developed strategies, including vision, mission, values, goals and objectives, to take their companies to greater profit. But more was needed to ensure that success was better defined and quantified for stakeholders. And senior management created measurement out of the dark technology, and saw that this was good.

But then arose myriad ways to generate, capture, slice, dice and report on measurements. Technology allows a limitless number of data points to be gathered during a given time period. The shop floor has its solutionsintegrated programmable controllers, HMI (human machine interfaces), MES (manufacturing execution systems) and CMMS (computerized maintenance management system). The executive suite has its ownintegrated ERP (enterprise resource planning), CRM (customer relationship management), SCM (supply chain management), HRM (human resource management), and PLC (product life cycle) applications.

Alas, many companies are sinking in a data ocean, regurgitating a never-ending stream of numbers from countless sources. Not all of it is useful, and much of it is misleading when it is used to measure the performance of the MRO function. But as we learned from the recent Maintenance Performance Metrics survey sponsored by Plant Services and Rockwell Automation, that doesn't keep management from trying. What should they be focusing on? How can it be done? Let's take a look.

Understanding priorities

The survey tells the story. Figure 1 shows that 78 percent of respondents said "production goals" are very often used by corporate officers for measuring manufacturing performance. This compares with only 56 percent of respondents who felt "uptime" was the key metric.

Figure 1. Importance ratings of measures that corporate offices use for evaluating manufacturing performance. Overall equipment effectiveness (OEE) is lowest.

When asked about priorities for the coming year, survey respondents saw cost-cutting as the corporate mantra, with 77 percent of survey respondents claiming that decreasing expenses was a major priority for the coming year. The #2 priority appeared to be improving uptime rates, with 64 percent of respondents saying it was important. Presumably, increased uptime translates into greater production capability and reduced downtime expense. A third priority was improving overall equipment effectiveness (OEE), which 54 percent of respondents felt was a major priority.

If you combine expense reduction, greater uptime and improved overall equipment effectiveness, you get the overarching objective for the management of assetsasset optimization. Thus, asset optimization can be defined as maximum uptime and overall equipment effectiveness at least cost.

Have we optimized our use of assets? No, we're not even close. So let's break the concept of asset optimization down further and show how a computerized maintenance management system (CMMS) can be a powerful tool for attaining the asset optimization goal. Each part of the definition is described in detail below.

Maximum uptime

Many phrases are synonymous with this important objective, including maximum asset availability, minimum equipment downtime and maximum equipment capacity. The larger the asset base, the more significant the investment required to compensate for lost production time. Suppose a plant has 10 production lines, each worth $10 million in replacement cost. If each line suffers an average downtime of 10 percent, then it's as if one line is down permanently, which costs the plant $10 million in equipment alone. This is compounded by potentially far greater costs and opportunity losses, such as:

Space and utility requirements for the "extra" production line.

Additional spare parts required to fix the equipment and kept in stock.

Other operating costs, such as equipment vendor support and licensing agreements.

Maintenance labor associated with servicing the downtime.

Operations labor that may be idle for part or all of the downtime period.

Customer service impact in meeting delivery deadlines.

Opportunity loss of production from unused capacity, that is, if you could sell whatever you produce, then more downtime means less sales revenue.

Note that downtime is not necessarily caused by breakdown. Setups, changeovers, cleanup, preventive maintenance and other planned activities may also decrease productive asset availability. Maintenance and operations departments can work together to minimize these disruptions to achieve still further cost reduction.

The role of the CMMS is not only to help monitor the extent and cost of downtime, but, more importantly, to assist in determining the root cause. By analyzing failure codes, using condition monitoring, tracking the history of serialized parts and components, deploying a troubleshooting database, and using other key CMMS features, equipment availability should increase, and the costs and opportunity losses should decrease.

Downtime isn't cheap. Well over half of survey respondents who knew their average cost of downtime estimated it to be at least $1,000 per hour. In terms of impact on the delivery of goods to customers, 43 percent of respondents felt downtime had some effect, and a further 47 percent felt downtime had a major effect. Therefore, for most plant environments, maximizing uptime is a worthwhile objective that can yield significant savings or revenue.

Maximum OEE

One of the most often overlooked or misunderstood objectives of the maintenance support function is ensuring maximum overall equipment effectiveness, or asset performance. This is, in part, because these terms are often mistakenly assumed to be equivalent to the term "uptime," as if overall equipment effectiveness is achieved by reducing downtime. This isn't necessarily true, nor does it tell the whole story.

Referring to the example above, suppose the 10 production lines vary with respect to production output. Line #4 might consistently have the highest average output of 10,000 units per day, and the lowest reject rate averaging about one percent of output. Unfortunately this line also has the highest average downtime at 14 percent.

The other nine lines produce from 7,500 to 8,500 units per day, but downtime is never greater than 10 percent for any of them. Reject rates range from two to four percent. Which machine has the highest overall equipment effectiveness?

Overall equipment effectiveness is defined in terms of the quality, quantity and consistency of output. By definition, line #4 has the highest overall equipment effectiveness, even though it has the lowest uptime. Maintenance must optimize both OEE and uptime simultaneously using tools, such as the CMMS, to track and analyze data.

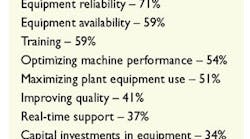

Table 1 highlights the tight relationship between the two metrics. Three-quarters of respondents specified "knowledgeable and skilled staff" as having a major effect on improving uptime, 71 percent specified "equipment reliability," and 59 percent said "equipment availability." Clearly, equipment reliability and the ability of staff to extract maximum overall equipment effectiveness or asset performance are key factors in maximizing uptime.

Table 1. Major factors for improving uptime. Least cost

Some companies do a great job at maximizing overall equipment effectiveness and uptime, but they do it by throwing a lot of costly labor, material and overhead at their problems. Would the OEE and uptime improve if the number of maintenance technician tripled, inventory of parts and components doubled, and millions were spent upgrading the maintenance shop facilities? Indeed it would, but asset optimization requires that maximum overall equipment effectiveness and uptime be achieved at minimum cost.

Thus, it's no surprise that survey respondents placed a high value on the "budget compliance" metric, with 53 percent stating that they always use budget compliance to measure performance of MRO activities at the plant level. This is about equal to the 52 percent of respondents that always use uptime to measure performance.

The CMMS does an excellent job of tracking and analyzing costs. For example, the whole concept of work order control pushes the concept of least cost. Work orders involve choosing the right labor and materials for solving a problem as efficiently and effectively as possible. Tracking planned versus actual labor hours on a work order and analyzing significant variances is one way of keeping labor costs to a minimum. Another way is through better scheduling, that is, ensuring that worker utilization is high, that people with the right skills do the higher priority jobs, and that more costly work is done first.

A CMMS inventory management module can also help reduce costs. Basic features, such as reporting on usage history and supplier history, can ensure that inventory levels are kept low, stockouts are minimized and the quality and service from suppliers is optimal. Advanced features can reduce costs still further. Barcoding parts and equipment to keep more accurate track of inventory is one example. Electronic data interchange (EDI) and, more recently, e-procurement are growing in popularity because they eliminate the high cost of paper-based purchase requisitions, purchase orders, invoices and receiving documents.

Also, a CMMS can reduce costs by better managing the assets themselves. Basic functionality, such as recording nameplate data and engineering specifications, goes a long way in keeping track of the millions or billions of dollars tied up in capital equipment and facilities. Standard reports, such as equipment downtime and equipment repair history, can expose equipment that is costing too much.

More sophisticated functionality then can be used to determine a problem's root cause. This includes analysis of complaint, failure, action and delay codes. The benefit is greater equipment reliability, more accurate repair/replace decisions, improved understanding of which vendors supply superior equipment, and better understanding of the optimal mix of predictive, preventive, planned and reactive maintenance. This, in turn, leads to lower costs.

What is the optimal mix of predictive, preventive, planned and reactive maintenance? Figure 2 shows the average of ideal percentages provided by respondents was 35 percent preventive, 18 percent predictive, and 12 percent breakdown or reactive maintenance. This is a 6:3:2 ratio. The actual time spent by respondents was, of course, much different than the ideal, namely 29 percent preventive, 10 percent predictive, and a whopping 33 percent reactivealmost triple the stated ideal.

Figure 2. Actual versus ideal percentages of time spent on maintenance activities. Barriers to asset optimization

When we put the components togethermaximum overall equipment effectiveness and uptime at least costwe get asset optimization, a formidable goal. While the CMMS goes a long way to help operations, engineering and maintenance management attain this goal, there are many barriers.

This provides insight into the most common views of the barriers to achieving higher levels of uptime, a key element of the asset optimization equation. Respondents say equipment age and budget constraints are major barriers, with 34 percent and 29 percent response rates respectively. When asked, "How much additional budget would you need to achieve corporate goals for uptime?" more than half of respondents said they would need their budgets increased by at least 20 percent.

However, these questions dealt with barriers to achieving only one component of asset optimizationhigher levels of uptime. Perhaps when considering the whole equation, throwing more money at the budget or paying for new equipment doesn't yield asset optimization. Uptime may improve, but not necessarily at least cost. It's therefore critical to examine other components of asset optimization on a case-by-case basis. A CMMS can be a useful tool for ensuring true asset optimization, for example, in performing a repair/ replace decision for aging equipment, conducting root cause analysis for repetitive high-cost problem codes, or using simple condition monitoring techniques to avoid costly downtime situations in the first place.

Measurement drives asset optimization

To achieve asset optimization, plant management and folks on the shop floor need a solid operational strategy that provides a game plan for achieving corporate goals, efficient and effective processes that support the strategy, and solid underlying information systems like a CMMS for planning, tracking results, critical analysis and decision support. Measurement is the means by which we keep score.

To be sure, measurement is a key factor in driving asset optimization. We know intuitively that the higher we raise the bar, the greater the pressure to excel. But which measures should we track and how often, and how many do we need, in what areas of the plant, with what targets? A typical CMMS can be configured many ways to answer these questions.

When you develop your own metrics, follow these simple guidelines:

Be absolutely certain that the measures and targets drive the right behavior along the shortest path to the overall company strategy.

Focus, focus, focus on a small set of key measures for each stakeholder.

Integrate measures across departmental silos, and allow consolidation/drill-down hierarchically from the shop floor to top management.

Ensure measures are broadly based to minimize unnecessary tradeoffs and don't fixate on measures related only to equipment.

Targets should be aggressive but attainable, to stretch the organization appropriately.

Use monetary and non-monetary incentives to reward achieving and surpassing targets.

The power of lean

Companies that have successfully implemented a balanced scorecard program are well aware of the power of following these guidelines. Adopting a lean manufacturing philosophy shows how using only a few measures can drive the right behavior, yielding drastic improvements to the bottom line. Traditional measures, such as quantity produced per hour or per work center, machine efficiency and variance to standard, are well-established favorites in the manufacturing sector. They keep people busy, machines humming, and loaded costs low compared to standard, but may lead to unnecessary work in progress.

By contrast, some typical lean measures and the more effective behaviors are subject to incentive. For example, operators must focus on reduced lead-time, work in progress, space, travel distance and number of times material is handled to improve plant efficiency significantly, without trading off product quality. Simultaneously, maintenance must concentrate on improved machine uptime through quicker response time, reduced number and duration of setups/changeovers, and greater reliability, without sacrificing product quality.

The lean philosophy provides a useful framework for determining appropriate measures and targets in harmony with the six guidelines. This is especially evident when incentives are used to reward superior performance. But it's surprising how infrequently even non-monetary incentives are used. A meager one-third of survey respondents said they were rewarded for meeting or exceeding uptime targets, and uptime is only one of many key measures.

A CMMS is an excellent tool for assisting in the pursuit of asset optimization. But it alone is not enough. Asset optimization requires, first and foremost, a solid operational strategy that reflects corporate goals, incorporating useful frameworks such as lean. Furthermore, efficient and effective processes must be established in light of the strategy, using enabling technology such as a CMMS. Finally, measures and targets must be defined following the guidelines outlined above, and in light of strategic objectives. As shown by the survey results, many companies have their work cut out for them to achieve asset optimization. On a more positive note, at least most know where they want to be and are eager to face the challenges that lie ahead.