Sponsored Recommendations

Sponsored Recommendations

Managing a plant's interior climate can affect plant productivity and efficiency. Proper humidification, in particular, benefits many manufacturing processes. Often, humidification can increase production speed and improve product quality. Some processes requiring strict humidity control include textiles, woodworking, printing, electronic and microchip fabrication, and processes that involve gluing, bonding and coating operations.

If a humidity-sensitive raw material doesn't have time to reach its equilibrium moisture content, its dimensions and other handling characteristics will change once it's on the work floor. This causes problems with equipment set-ups or the glues and laminates to be applied. Dry air also prevents static electricity from dissipating spontaneously.

Meeting indoor air quality standards often requires pulling large volumes of outside air into the plant. Sometimes the dock doors on an otherwise well-sealed building are left open for extended periods, bringing in more unconditioned outside air. If the weather is cold and dry, the result is a dramatic, rapid decrease in the indoor relative humidity.

Similar outcomes result when older machines are replaced with faster, higher energy machines. The extra heat they release indoors can drive down plant humidity levels. But more important than production problems are the health and comfort effects that arise from working in an environment of extremely low humidity.

Sometimes production machinery that responds in a predictable manner when humidity levels drop can serve as a hygrometer. Given suitable warning, a plant manager will be able to diagnose correctly any issues relating to humidity. It may be that knowledge of moisture content and humidity systems have more to do with the success of a company than originally believed.

Raising humidity and plant efficiency

Make no mistake about it; adding moisture to the air requires energy consumption. For example, a fogging device uses 1,000 lbs of water per hour (lbs/hr - 2 gallons per minute (gpm). This is only about 3 percent of the electrical energy atomizers based on compressed air or ultrasonics consume, and only about 1 percent of the energy a steam humidification system uses.

Foggers don't require compressed air or heat. At an operating pressure of 1,000 psi, fog droplet size is in the range of 10 microns (less than one-tenth the diameter of a hair). Because fog droplets have an enormous surface-to-volume ratio, they evaporate quickly in dry air.

At plants with large internal heat loads, it's sometimes impossible to achieve adequate humidification of the air moving through the plant's HVAC ductwork. The solution often is a matter of installing fog nozzles directly over the manufacturing floor.

Fog system basics

The basic operation of a fogger is straightforward. High-pressure water is pumped to fog nozzles, where tiny openings shoot an ultra-fine jet of water against a metal pin to produce a shower of microdroplets. The concept is similar to covering the end of a garden hose with your thumb. The difference is merely the droplet's size.

For effective humidification, evaporation must occur in a matter of seconds. Small droplets remain suspended in the airflow, floating around objects easily. If there is no air movement, droplets evaporate as they approach the relatively warmer machinery or dryer air. Therefore, the fogger's secret is in the droplet size distribution. The size of most of the droplets in the fogger's spray is 10 microns. Most of the water volume consists of droplets smaller than 20 microns across.

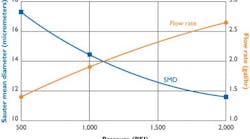

When measuring droplet size, it's important to consider distance from the nozzle and the conditions produced when billions of droplets are released almost simultaneously. Studies have shown certain nozzles operate in the "sweet spot," where just enough water is delivered with just the right force. A nozzle operating at 1,000 psi produces a 14-micron droplet size on the Sauter Mean Diameter scale (see Figure 1). With a seemingly minor adjustment, the force splitting the water into droplets loses significant strength.

Figure 1. This scale shows the point where the right amount of water, and the right amount of force are most effective.

Water quality is important

A typical water analysis reveals as many as 25 constituents and variables, the most important of which are hardness, turbidity and mineral content. If water hardness exceeds five or six grains per gallon, a water softener will be needed to prevent mineral buildup on the nozzles.

If system performance appears to diminish, it's likely filtration is the problem. The maintenance routine includes checking the filters every week to ensure they're not dirty or clogged. If the upstream filters fail, minerals can collect in the nozzles, eventually clogging them. Some fogger systems feature nozzles with removable filters for easy maintenance. The best way to do filter maintenance is to put a pressure gauge on the entrance and exit side of the HIF filter, and change the filters when there is a difference of 10-15 psi from normal pressure drop across the filters.

Design example

A printing plant wanting to maintain 50 percent relative humidity on its 100,000-square-foot plant floor used fog humidification to atomize 2,338 lbs. of moisture hourly, a rate derived from calculated machinery heat loads and an outside air exchange of 7,000 cfm. The plant determined its needs required sending 4.7 gpm of high-pressure water through 2,500 ft. of fogline tubing that supplied 334 nozzles positioned over the plant floor. Using the plant's existing reverse osmosis water supply ensured no particulate would dust the shop floor after the fog droplets evaporated.

Paper is brought onto the work floor and the protective covering is slit open to expose the paper and allow its moisture content to equilibrate.

The system uses two zones to isolate the storage areas from the work floor. The largest zone is the open work floor with plenty of motors and a larger heat load. The smaller zone includes smaller machine rooms and the storage area, housing 16 tons of raw paper. A two-zone humidistat connected to motorized ball valves maintains both areas at 50 percent relative humidity while the HVAC system independently maintains 72 F dry bulb temperature. A third valve operates a purge to drain the system automatically after one week of non-operation during the summer. A third humidistat serves as a safety cut-off in the event the primary control fails, which would otherwise cause the fogger to run continuously.

Thomas Mee is CEO of Mee Industries Inc. He can be reached at [email protected] or 626-359-4550.

Figure: Mee Industries Inc.