Components of large industrial fan impellers have natural resonant frequencies, which, if excited during operation, may cause vibratory stress and fatigue. The result may be cracking or destruction of certain components. Fortunately, several simple field tests performed with fairly inexpensive equipment can measure component vibration response and anticipate frequencies that will be excited after installation.

One such testthe impact, or impulse excitation techniqueoffers several advantages over the swept-sine wave excitation test. It can suggest corrections to prevent natural frequency excitation.

Natural frequency excitation

Component parts of an industrial fansuch as the shroud (rim), webplate (center disk) or impeller bladehave a natural frequency of vibration. Geometry, material of construction and points of connection to other components determines this resonant frequency.

It's possible, but not desirable, to excite any of the possible natural frequencies by some outside force. A simple example would be the blade of an axial flow impeller vibrating as a cantilever beam. This vibration type is not to be confused with unbalance, bearing vibration or shaft natural frequency. Consider this example.

A large sintering plant had a 98-inch diameter axial flow impeller with several cracked blades. In fact, one blade tore completely loose from the hub. A vibration analysis revealed three natural frequencies or modes:

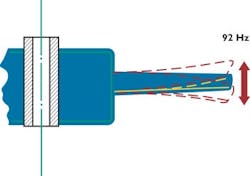

At 92 Hz, the blade vibrated as a cantilever with its base anchored and the entire blade flexing up and down (see Figure 1).

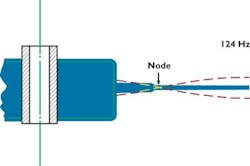

At 124 Hz, the blade exhibited one node near the transition point between the thicker and thinner sections of the blade (see Figure 2).

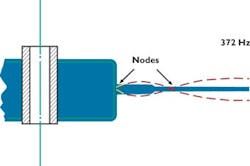

At 372 Hz, the blade exhibited a node at the base of the blade and another just beyond the transition point between the thicker and thinner sections (see Figure 3).

Figure 1

Figure 2

Figure 3

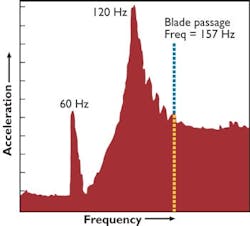

The 10-bladed impeller operates between 680 rpm and 750 rpm, which produces a blade passage frequency between 113 Hz and 125 Hz. The blade passage frequencyits operationally induced frequencycoincided with the second resonant frequency. As a result, the blades developed cracks at the node location. A redesigned blade featuring a beefier cross section raised the resonant frequency to 152 Hz, which solved the problem.

Additional variables

Determining the natural frequencies of the component parts is only part of the job. One also must anticipate which frequencies are likely to be excited. Among the variables to consider are:

Operating speed.

Blade passage frequency.

Rotating stall caused by partially closed inlet dampers.

Stack- induced and duct-induced vibration.

Mechanical drive vibration caused by bearing problems, coupling misalignment and other problems.

Shaft torsional frequency, especially in variable speed drive applications.

Impeller test preparation

Preparing an impeller for testing requires suspending it on soft supports so the shaft centerline is horizontal. There should be no contact between the fan and the floor or other obstruction. The test area should be free of ambient noise and vibration.

Usually, the following centrifugal fan locations are tested:

Shroud outside diameter, midway between two blades.

Shroud inside diameter, midway between two blades.

Web outside diameter, midway between two blades.

Blade tip.

Blade inlet, midway between hub and shroud.

On axial fans, only the blades are tested, but they should be tested at several points to determine mode shapes at each resonance.

Testing procedure

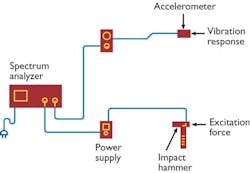

Set up the test equipment as shown in Figure 4. Attach the accelerometer to one face of a metal component using beeswax as an adhesive. The attachment will be reliable for frequencies below 1 kHz. Magnet mounts are not recommended because there is some risk the accelerometer will jump on hammer impact. For extreme temperatures or high frequencies, attach the accelerometer using a screw stud or a suitable adhesive.

Figure 4. Test equipment setup.

Connect the output of the impact hammer's integral force transducer to channel A of the spectrum analyzer, which should be equipped with a threshold signal trigger. Connect the accelerometer to channel B via the charge amplifier.

Then use the hammer to strike the component on the side opposite the accelerometer. If the blade has hollow sections, or if tight clearances prohibit access to both sides of the component, the hammer can strike directly beside the accelerometer with minimal accuracy degradation. However, doing so shifts the signal's phase by 180 degrees. The hammer should strike each location four to eight times, allowing time between impacts for the vibration to decay. Taking several averages greatly reduces the effects of ambient vibrations and non-linearities.

For this application, the transfer function is channel B input (acceleration) divided by channel A input (force). Set the spectrum analyzer to display a graph of transfer function versus frequency (see Figure 5). This information can be used to calculate compliance versus frequency using a standard formula.

Figure 5. Transfer function as a function of frequency.

The analyzer also may be used to generate useful information about mode shapes. It requires moving the accelerometer to different points on the impeller while keeping the excitation point constant. Alternatively, the excitation point may vary while the accelerometer remains constant. A mode shape can be defined by comparing the phase values of the points at each resonance.

Analyzing the results

Examine the graph of transfer function vs. frequency. Look for evidence of high vibration at or near operationally induced excitation frequencies, such as the blade passage frequency. Determining whether vibration is too high requires predetermined limits for the maximum compliance within a specified deviation from an excitation frequency.

In terms of corrective action, an extra brace or liner bar may be added to increase stiffness and raise the component's natural frequency. Knowing the mode shape is useful when deciding what type of stiffener to use and where to place it.

Dan Banyay is a manager and Les Gutzwiller is vice president of technical services and chairman of the board at Robinson Industries, Inc., Zelienople, Pa. They can be reached at 724-452-6121.

Figures: Robinson Industries, Inc.