By Chad Larrabee

The biennial event, ComVac, is the world’s largest fair for compression and vacuum technologies in Hannover, Germany, April 24-28, 2017. This year’s show promises to be one of the largest ever with vital topics in the industry.

The trending topics at ComVac 2017 include:

- Focus on systems approach

- Optimization strategies and sustainability

- Connected utilities in Industrie 4.0

- Reliability

Systems approach

A show for compressed air equipment can easily overlook the importance of the interdependencies of the entire system. The system consists of supply, transmission, and demand. At ComVac, we are making sure we look at the entire lifecycle of a compressed air system and how to ensure the system is working together as a system to deliver reliability, energy efficiency and the quality of air needed for the particular application.

Optimization and sustainability

Do you have the ability to create and sustain an optimized air system? We call it Sustain. Ability. Making sure you have the know-how to minimize waste and deliver the right air quality at the right pressure for the lowest possible cost can be a challenge. Often, plants do not have key performance indicators (KPIs) around compressed air usage. Measurement is the first step to proper management of a compressed air system. Proper analysis combined with expertise will generate recommended improvements. Then, controlling the improvements to deliver lasting results is the key to Sustain. Ability. Why is this important? Certainly, a company’s bottom line is impacted by operating costs, but more importantly, regulation is coming to ensure improvement in power consumption. Energy savings is the central objective of the European Union (EU). The EU Member States have agreed to reduce primary energy consumption by 20 percent by 2020 and by at least 27 percent by 2030. An increase of the target to 30 percent is currently being examined.

Connected utilities and Industrie 4.0

There is quite a bit of communication and activity around the term “Industrie 4.0,” which recognizes a 4th revolution in the industry – the Industrial Internet of Things (IIoT). Industrie 4.0 emanates from ComVac’s home country of Germany, one the world’s largest industrial economies, and while IIoT and Industrie 4.0 are not the same, they are very similar. From manufacturing execution systems (MES) to connected utilities like compressed air, the opportunity to capture data is now a reality and the challenge is assimilating that data into useful, proactive measures. Adaptive controls and diagnostics are emerging at an increased rate and the ability to access and control or take action remotely is also improving every day.

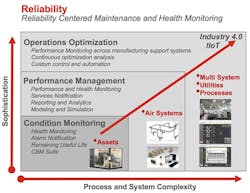

Redefining reliability

An aspect of Industrie 4.0 is delivering a predictive component to failure, allowing the user to take action before failure happens, or more importantly, design a system which is less likely to fail. Technology is emerging in compressed air to deliver both more reliable system designs through modeling and simulation and remaining useful life predictions for proactive remedies which avoid unplanned downtime. This predictability through design and diagnostics is redefining reliability.

ComVac 2017 will be an exciting show and Ingersoll Rand will be there to help lead these important industry trends. To learn more about the solutions that will be available at the show, visit www.ingersollrandproducts.com/en-us/tradeshows-events/trade-showCOMVAC.html.

Ingersoll Randcan be found at ComVac at Hall 26, Stand C12