Maintenance Mindset: Honoring the people and programs advancing plant reliability and operations

Welcome to Maintenance Mindset, our editors’ takes on things going on in the worlds of manufacturing and asset management that deserve some extra attention. This will appear regularly in the Member’s Only section of the site.

What would you say is more difficult – building a strong reliability program at your facility, or maintaining it over the next 5+ years?

Admittedly this is sort of a trick question, as both are difficult to achieve. Building a reliability program from scratch involves a combination of training, PM improvement, and technology selection that is centered on keeping critical assets from failing unexpectedly.

However, the skills required to build a reliability program are very different from the skills required to continue that success in the face of employee churn, leadership turnover, and unpredictable changes in the business landscape. Also, without a champion who can communicate the value of the program to all levels of the organization, the program risks slowly fading away.

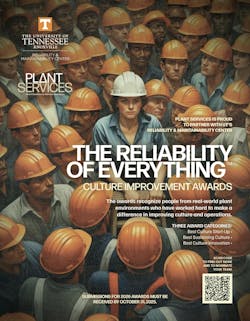

This is why, starting this year, Plant Services is very proud to partner with the University of Tennessee’s Reliability and Maintainability Center on the Reliability of Everything™ Culture Improvement Awards. These awards recognize people from real-world plant environments who have worked hard to make a difference in improving culture and operations, maximizing the use of asset data and engaging workers at all levels.

Awards are given in up to three different categories (Culture Start-Up, Sustaining Culture, and Culture Innovation) and are based on three criteria:

- Measured improvement in R&M metrics (25%)

- Measured improvement in culture and impact on R&M/operations (50%)

- Documented journey/process used with lessons learned (25%)

It was my pleasure to announce this partnership with Dr. Klaus Blache at the 2025 MARCON Conference, both as a continuation of the good work begun in 2019 by Efficient Plant magazine and the RMC, and as a celebration of winners past, present, and future. Everyone here at Plant Services is thrilled to be part of this celebration of reliability culture and maintenance program success.

For further information on how to nominate your plant for a Culture Improvement Award, please visit the nominations page on the UTK-RMC website.

Plant Services to participate at Fluke Reliability's Xcelerate 2025

Also coming up later this month in Austin TX is Fluke Reliability's Xcelerate 2025 event, from March 18-20, and I'm looking forward to being on several panels and event sessions that focus on the state of maintenance and reliability.

This conference has evolved from a primarily software-focused user group event for Fluke's eMaint CMMS into a thought leadership event that addresses the technologies that are changing the face of manufacturing, from artificial intelligence to the latest in predictive maintenance tools.

I'll be giving a short presentation on what's keeping manufacturing leaders up at night and moderating a panel discussion on that topic, as well as participating in several other panels including how industry is (and is not) responding to the ongoing skills gap. I hope to see you there!

Call for participants in compressed air research project

Are you a junior sales consultant, sales engineer, or independent consultant working within the compressed air industry?

If so, technical expert and regular Plant Services contributor Ron Marshall would like to hear from you! Ron is working on developing future training for compressed air specialists, and is curious about the hiccups and hurdles that better training might help you overcome.

Perhaps your challenge is effectively measuring and interpreting data from industrial instruments, producing detailed and actionable audit reports, or passing a certification exam.

If this sounds like you, please consider reaching out to Ron to share your experiences by answering a few questions on this form: https://forms.gle/JXMa3ehDY4Tipbkh7