Whether used for cooling or the process itself, the raw water drawn from lakes, rivers and reservoirs must first be strained to create acceptable water for use. In many industries this means continuously straining tens of thousands of gallons of water per minute to remove dirt and debris that can wreak havoc on critical process systems and equipment.

In essence, the raw water strainers that accomplish this task are the first lines of defense for the entire plant’s system. Choosing an inadequate strainer can lead to high maintenance and operating costs, periods of insufficient water supply, damage to process equipment and expensive downtime. Worse, the straining media of an overwhelmed water strainer can rupture or collapse, permitting debris to compromise critical plant operating components. In the power industry, for example, clean water is crucial for a variety of tasks including, among others, extending the service life of turbine seals and for the protection of spray nozzles and heat transfer equipment.

Unfortunately, such failures are not unusual, particularly when the strainer design does not allow for sufficient straining surface area. In applications that use raw water from rivers, for example, single-basket strainers sometimes become overwhelmed and clogged during periods when there were high volumes of debris in the water due to seasonal conditions such as rainfall carrying dirt, leaves and other loose particles into the water supply.

|

View more strainer content on PlantServices.com |

“You never really know what you’re going to experience with river water,” says Sang Partington, senior engineer with PPL’s Generation Technical Group. “It changes from season to season. During autumn and high water flow in the river you may have a lot of debris such as tree branches, leaves and other solids in the water. Therefore, your water strainer has to be able to handle the solids and still maintain a continuous volume of water flow.”

Which strainer technology?

Water strainers for mass raw water filtration have been around for decades, and today manufacturers offer a variety of designs, including those that operate automatically. One of the more significant advances in strainer design occurred in the 1960s when the first multi-element, automatic self-cleaning strainer design was developed.

This strainer design was particularly significant because it provided a durable and reliable alternative to the classic basket-type strainer that — although it sometimes carries a lower price tag — also is limited by its strainer surface area, which can quickly become clogged and force excessive cleaning cycles (backwashing) and reduced water for process requirements.

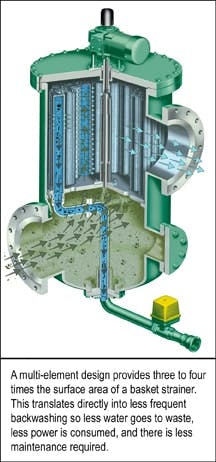

By replacing the basket with multiple tubular elements, the design provides three to four times the straining surface area of a typical basket strainer. As a result, debris and solids — including from seasonal peaks — are efficiently removed without downtime. The increased surface area of the multi-element design allows for fewer backwashes, equating to lower operational costs, less maintenance and greater overall efficiency.

Optimizing water flow at PPL

About five years ago, PPL Senior Engineer Partington noticed that the old, basket-type water strainers at its Brunner Island plant required high maintenance and continuously shifted to backwash mode. “The old system was constantly backwashing,” he says.

At PPL’s electric power generation utilities, the priority is maintaining sufficient volume and pressure, although there is certainly concern about the debris and other solids that can be in the rivers that feed water to the coal-fired plants.

PPL began to upgrade the raw water strainers at its Brunner Island and Montour plants, both feeding off the Susquehanna River in central Pennsylvania. Both are large generating facilities with about 1,500-megawatt capacity, and it is critical to ensure sufficient clean water to keep the plants on line continuously.

Partington says the outflow of clean, filtered water through the strainers also was at lower-than-optimal volume when backwashing was taking place, so he began to look for a more advanced and efficient strainer technology. After reviewing several more advanced designs, Partington selected the multi-element strainer from R.P. Adams.

Although initially designed for raw water applications, the R. P. Adams multi-element strainer can remove solids as small as 25 microns. So the multi-element strainer can be used as the first line of defense in water filtration, or it can be installed at a point of use for critical plant operations requiring fine levels of separation.

Another significant feature of the multi-element design is in the engineering of the backwash mechanism. With basket strainers, the backwash mechanism comes into direct contact with the straining media. This can be problematic because large, suspended solids often encountered with raw water can become lodged between the straining media and the backwash arm. The result is straining media damage and/or rupture that can compromise plant operations.

The multi-element design utilizes a tube sheet to separate the straining media from the backwash mechanism. This prevents the backwash mechanism from coming into contact with the media and damaging the elements caused by large solids becoming lodged between the media and the backwash arm.

Furthermore, the multi-element design provides three to four times the surface area of a basket strainer. This translates directly into less frequent backwashing, so less water goes to waste, less power is consumed and there is less maintenance required. Partington’s decision was also due to the fact that these strainers could provide the necessary plant water requirements even while in backwash mode.

“The new units will not backwash unless the differential pressure of the strainer is high enough to activate backwashing automatically or by the timer, thereby saving us money on the power consumption,” Partington explains. “We should also save significant money on maintenance, too, but we don’t know how much yet because the units are so new.”

Partington also appreciated that R.P. Adams was willing to customize the strainers to meet PPL’s design specifications, and also offered an exchange program whereby he could replace the strainer elements to a different micron size if he needed to do so.

“The element exchange program allowed us to go for greater straining efficiency, which helped us optimize the raw water system,” he says. “We elected to exchange the original elements for a smaller micron size. It has worked very well, so we’re going to stay with that size for that particular installation. But as we continue to upgrade our water strainers at various locations, we can do the same thing — in effect, fine-tune the solid removal and water flow as the situation warrants.”

To date, PPL has upgraded to eight R. P. Adams strainers at the Brunner Island plant, and has installed the first unit at its Montour site. PPL intends to standardize on the R. P. Adams design, and will phase-in new strainers as opportunities arise.

For more information, call (800) 896-8869, e-mail [email protected] or visit www.rpadams.com.