Editor's Note: This post was sponsored by Augury.

From the executive suite to front-line plant personnel, the devotion to avoiding unexpected downtime and minimizing planned downtime runs deep.

Earlier this year Plant Services and Augury conducted a research survey. Augury supports its customers by providing them with superior insights into the health and performance of their machines. The Machine Maintenance & Reliability study was designed to explore the common challenges to machine health faced by industry, and how organizations are putting it into action.

James Newman is Director of Market Strategy at Augury, with more than 20 years of experience focusing on understanding how assets and plants can operate better and more efficiently, and how that can be augmented by technologies. He recently spoke with Plant Services editor in chief Thomas Wilk on the universal challenges that industry is facing, and how data from the survey shows how those challenges might be solved together by those on the front line and in the C-suite.

Q: The survey forked into two groups: corporate respondents and frontline respondents. What knowledge did you seek to gain from those two sides of the business?

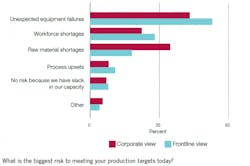

A: There’s a really interesting dynamic between the corporate persona and the plant persona. The corporate folks are looking across a wide variety of assets and facilities. The plant people are focused on their day-to-day. Splitting it up like this allows us to get both pictures. Are they seeing the same challenges? Are they seeing different ones?

Q: Both sets of respondents were asked about their key operational challenges, and both groups cited supply chain disruptions as their top challenge. Right now in Chicago, I can’t find 3oz Dixie cups. That’s the latest supply chain quirk; last year, it was baseball cards, right now it’s Dixie cups. However, other top challenges included unplanned production downtime and workforce skills gaps or upskilling issues. Maintenance teams have a lot of immediate control over those. What are your thoughts on overcoming these operational challenges?

A: We can start with unplanned downtime and workforce challenges. Can technology help an overstretched workforce reduce unplanned downtime? Yes, but up-leveling workers shouldn’t mean they become data scientists. Solution providers can boil all the data down into something actionable, that’s easy to adopt and build into your workflow.

When there are supply chain shortages, unplanned downtime becomes even more important because in many of our industries, you only have a limited amount of material. You have to eliminate waste and unplanned downtime is often a cause of waste.

Q: I want to move to a data point involving mechanical problems and the ability to visualize the condition of the asset: 69% of frontline respondents said the most common cause of unplanned downtime is mechanical problems. Yet 67% of respondents said they don’t have the ability to visualize the real-time condition of their critical assets. That’s only a 2% delta. Did that surprise you when you saw it? Is this your experience when you go into plants?

A: It’s very common and it’s not entirely unexpected. Until recently it was cost-prohibitive to “sensorize” your existing assets. We also saw in this survey that most teams still do preventive maintenance. Preventive maintenance is a known way to do business but not necessarily the best way to do business. If you want to solve unplanned downtime and solve production challenges, you can’t stay there.

Q: More than 80% of respondents said they had information on why failures are occurring. It could be an FMEA, it could be root cause analysis. However, less than half of frontline workers knew what failures cost the business. That surprised me. I thought that more respondents would have an idea of the value of their work, i.e., the cost of a minute of unplanned downtime, and that they would have an incentive to minimize those losses. Your thoughts on that?

A: Every single time it surprises me that people don’t know this. I believe it comes back to how people are measured. Maintenance teams aren’t measured on things that drive value for the bottom line of the business, apart from cost. But if you compare cost to revenue and production loss, those two things are not on the same scale.

Maintenance and reliability teams are measured on the cost of maintenance, or our cost of parts, our cost of overtime but not on sustainability and productivity and revenue growth. Even OEE, which is the gold standard for how well you’re managing your plant, doesn’t relate directly to profitability. The metrics on which they are measured don’t drive people to care about the cost of downtime.

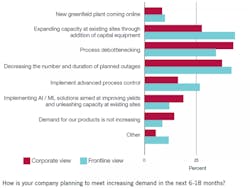

Q: For this survey, frontline workers were asked how important it is to standardize a global maintenance reliability program across all their manufacturing sites. Only 54% said it was either very important or critical. Now, there are a lot of debates you can walk into a maintenance event with and start a fist fight in the room. This usually isn’t one of them. People tend to agree that standardized work is key to success. What do you make of that 54%?

A: Yes, every plant is unique. Even if they were built to spec the first day, the second day, they no longer were exactly the same. Those differences have to be accounted for in maintenance and reliability strategy. But now we can say, “What is the data telling us about the right way to manage assets at the plant level? And what can we learn from that in order to learn across corporate strategy?” The corporate strategy can now be informed by data from the assets that are driving individual maintenance strategies.

It also means, we can look across plants and begin to understand why the best and worst plants perform the way they do. We can now ask, “How do I bring this plant up while maintaining the high level of another plant?”

To access the “Machine Health is Business Health” report, visit info.augury.com/PS

This story originally appeared in the April 2022 issue of Plant Services. Subscribe to Plant Services here.