This article seeks to dispel common misunderstandings that surround the practice of lubricant (oil) analysis with regard to manufacturing equipment in industrial plant settings. Let’s start by asking: What is the real purpose and value of oil analysis? While answers depend on who you ask, most agree that the perceived value depends on the individual engineer’s or technician’s experience with oil analysis and the level of insight they have about the potential of this approach. The more the user is aware of the great potential of a predictive, proactive condition monitoring method, the more possibilities to extract the full value.

Technology challenges

Like any other technology, oil analysis techniques evolve and change to meet pressing industry demands. Therefore, it requires a curiosity to explore, study, and discover the latest updates and trends that result in the continuous improvement of manufacturing processes in general and lower maintenance cost while extending run life of equipment. Additionally, one needs to be aware of their particular facility’s operational context when defining the goals and scope of an effective oil analysis program, ideally based on state-of-the-art condition monitoring techniques.

Monitoring resources

A given facility may monitor its equipment, machinery, and components for oil analysis purposes via an online monitoring system or “by exception.” Since candidates for oil analysis are extensive, it makes sense to consider condition monitoring requirements and budgeting constraints upfront. The below guidelines on oil analysis hardware and tests are useful when setting up your program:

- online sensors—to monitor main parameters, such as viscosity, moisture, wear, particle counting, and lubricant chemistry

- field analysis instruments and kits—to monitor main parameters plus acid number, base number, and quick-wear particle morphology (see Figure 1)

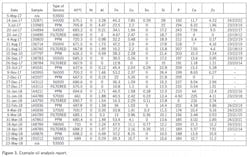

- routine oil analysis—performed by laboratories, either as independent services or as a support service to the supply of lubricants or other products (see Figure 2)

- advanced oil analysis testing (provided by specialized laboratories)—to obtain deep diagnostics of the lubricant in-service conditions for failure investigation of lubricants and machines.

It works well to combine the above-mentioned resources with specific frequencies for monitoring parameters based on equipment criticality, the severity of operational parameters, reservoir volume, and failure modes. The following contribute to a comprehensive condition monitoring plan:

- online sensors—continuous monitoring of fluid parameters

- field lab and test kits—frequent lubricant monitoring, e.g. on a weekly basis or run as required (supports immediate decision-making)

- field inspections—daily or weekly lubricant checks, such as color, presence of foam, moisture, or sediments (help with identifying abnormal conditions occurring in the machine or lubrication system)

- routine oil analysis (supported by an external lab)—at a frequency that typically goes from 1 to 4 months, or at different intervals depending on specific goals

- exception analysis—a one-time task as part of the routine analysis or by a specialized laboratory, either for failure investigation or at extended intervals for a deeper lubricant condition monitoring.

Oil analysis is performed at various times throughout the lubricant life cycle, such as during purchase, installation, and use.

- Lubricant selection—It is good practice to test lubricant performance before applying it to the machine; in some cases, this includes running similar tests on competitive products to determine which one has the most suitable performance for the expected application.

- Lubricant acceptance—Analyze a sample of incoming lubricant to check its level of cleanliness, dryness, or even to verify it is the correct lubricant and has the expected properties.

- Lubricant in storage—After long-term storage, a lubricant may lose some of the originally designed performance; proper sampling and testing help define its usability. Make it a routine to run periodic tests on lubricant while in storage to verify the cleanliness and dryness before installing it in the machines.

- Machine and lubricant condition monitoring—This is the sampling plan commonly associated with traditional oil analysis; the goals being to determine the lubricant health, contaminants, and machine wear. Another goal can be to determine the optimum lubricant change interval, or the moment the lubricant must be changed out.

- After a machine or lubricant failure—Run specialized sampling and testing to find out root causes of failure.

Designing an effective oil analysis program

The doors open for the design and setup of a world-class oil analysis program when the potential of this strategy is paired with the reliability needs of the facility or fleet. The condition monitoring of machines, lubricant, and operations, in their various modes, come into play with lubricant analysis. The monitoring plan can combine the different resources of oil analysis with other technologies to get the best information on the machine’s operational conditions. Defining the specific goals of the program will help identify which assets, frequencies, sampling, testing, and other lubricant-related procedures are necessary.

Selecting assets to monitor

Although every facility is different, certain factors typically determine the selection of machines/equipment to be monitored, such as:

- economic penalty of failure—downtime costs or business interruption

- repair costs, as well as difficulty to repair the equipment

- fluid environment severity, e.g., pressures, load, temperature, speed, lubricant contaminants, and duty cycle

- failure modes detectable through lubricant analysis

- machines representative of a fleet

- machines that will have the oil change optimized

- machines with significant lubricant volume—gearboxes above 5 gallons and hydraulic units above 20 gallons (This criterion varies across industry types.)

Interpreting oil analysis reports

Oil analysis reports generate information about the machine condition, lubricant health, and existing contaminants (see Figure 3). This information can be analyzed and interpreted at three levels: 1) the last sample results, 2) trends of the results for a single piece of equipment, and 3) statistical analysis of historical data for a fleet to diagnose fleet trends.

To interpret the results with the best possible precision, the technician interpreting the report information should have access to the current condition of the machinery and recent maintenance actions taken, as well as the operational context of the equipment. Interpretation provided only by the laboratory may fall short in detecting some of the above-mentioned sources of information, introducing some natural imprecisions into the diagnosis.

Professional oil analysis program design

An oil analysis program based on condition monitoring will be as good as your planning, implementation, and data interpretation. This article scratches the surface, in an attempt to raise your interest in designing such a program. It will pay off in the long term as machinery run life is increased and maintenance costs are significantly lowered.

This story originally appeared in the March 2022 issue of Plant Services. Subscribe to Plant Services here.

Alejandro Meza is a reliability engineering services professional at Allied Reliability with more than 20 years of experience supporting machine reliability optimization through Reliability-Cenered Lubrication (RCL), oil condition monitoring, and quality assurance. He can be contacted at [email protected].