Data integrity affects your whole operation, from inventory management to order fulfillment. Having accurate, complete data is especially important when it comes to maintaining your equipment. That’s why work order data is such a critical aspect of data integrity, and manufacturers must prioritize accordingly.

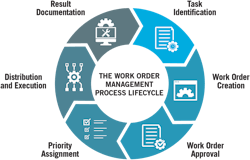

Work orders should be the source of truth for the maintenance or repair of each asset in your facility. They should provide complete and accurate information about the asset, its maintenance requirements, priority, and dates maintenance tasks were completed. A complete work order should also include details about the work to be done, the components and resources needed, and more (see Figure 1).

All too often, however, work orders are incomplete. People skip important parts of a work order or leave them blank to speed up the process, and this can lead to major gaps in their maintenance documentation, eroding data integrity and making it difficult to pinpoint problems later on down the line. For example, it is not uncommon for manual work orders to leave out key information about model numbers and manufacturers, or neglect to give details about exactly where the problem is occurring and how long it has been going on.

Managing work orders effectively and keeping pristine maintenance records can seem like a major challenge – not to mention a time-consuming endeavor. Your staff probably needs to change some of their habits. However, there are also many tools available to help keep your maintenance data clean, accurate, and up-to-date without a lot of extra effort. In this article, I’ll review some of the best ways to improve work order management throughout your facility.

How can you improve work order management in your organization?

Here are some of the best ways to get your team on track so that you see improvement in this area.

Tactic #1: Assign responsibility. It helps to give one person the ultimate responsibility for ensuring that work orders throughout the facility are filled out accurately and completely. You may want to hire a new employee, or you can assign the task to someone on your maintenance team. Whoever takes responsibility for work orders should regularly do checks to look for problems. Often, just knowing that there’s someone keeping an eye on things is enough to drive major improvement.

Tactic #2: Train your staff. Make sure that everyone on your team knows how they’re expected to fill out work orders. If you’re using a Computerized Maintenance Management System (CMMS) software, ask yourself these questions:

- Do all your employees understand how to use the CMMS system?

- Are all of your employees actually using the CMMS system? If not, why?

Hold regular training meetings where you go over any changes to the system. You can also use this time to talk about patterns you’ve noticed in work order completion. In addition, make sure all your new employees get a thorough onboarding. Even if they have years of experience, every plant is unique, and you want to make sure that all employees are up to speed on your system.

Tactic #3: Hold regular audits. On a regular basis (for example, every quarter), go through all your work orders and check to see if they’re accurate and complete. You can perform the same audit on a larger scale once a year as well. These audits will be easier to carry out if you’re working with a good CMMS that saves and stores your data. The audits will also give you a sense of how you should focus upcoming training sessions.

Tactic #4: Hire a data analyst. Some operations choose to hire a data analyst to look over the data and spot patterns. Where can your team improve? Where are your strengths and weaknesses, in terms of data integrity? While this tactic might not be right for every plant, having a dedicated data analyst role can provide a lot of value. Another option is working with a CMMS to help you assess your progress in different areas.

Tactic #5: Get regular feedback from the field. Communication is important in this area. Make sure you’re getting feedback from your maintenance team on a constant basis. Are they having any issues with the work orders they’re receiving? What kinds of problems are they experiencing? You can use that feedback to improve your training sessions. You can also use your CMMS to track metrics like mean time to repair (MTTR) and understand how that correlates with work order completion.

Tactic #6: Create templates and task lists. Make it easy for your team to fill out work orders by building templates such as a built-in task list, so that whenever someone generates a work order, it puts the task list in automatically. Your maintenance teams can access that list on their mobile devices and check off tasks as soon as they’re completed, so it’s always easy to track the progress of a particular job.

Building a better culture around work orders takes time. But if you give your team the right training and tools, you’ll quickly start to see improvements that will save you time and costs in the long run.