Build a workflow process that helps you better manage your maintenance team

Workflow describes the maintenance process for how and when a work request becomes approved, planned, scheduled, and executed. Wonderful opportunities present themselves for better management attention throughout the workflow.

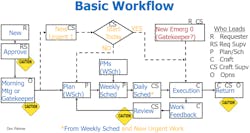

Figure 1 shows a general workflow process. This diagram considers a five-level priority system: 0 – Emergency (Start now), 1 – Urgent (Complete this week), 2 – Routine High (Complete in 2 weeks), 3 – Routine Normal (Complete this month), 4 – Routine Low (Can take longer than a month). A well-performing plant might have about 80% of its work being routine (Priorities 2-4) and 20% being emergency or urgent (Priorities 0 & 1). Emergency work might be only about 3% of the entire total work.

Routine work starts at the top left with a Requester submitting a request, sometimes through their Supervisor. The request then flows to either a morning meeting or Gatekeeper (some plants have both) where the “work request” becomes a “work order.” (Many workflows simply call the request an unapproved work order.) Planners then determine scopes and procedures for the maintenance work and see if parts and tools are available.

At the end of the week, the Scheduler (many times the Planner) creates the next week’s schedule. The Craft Supervisor then creates (or adjusts) daily schedules as the week unfolds. Craftspersons execute the work and return the assets to service with Operations. Craftspersons also provide work feedback, especially if they did anything different from the job plan and where the plan might be improved for the next time.

Palmer's Planning Corner

This article is part of our monthly Palmer's Planning Corner column. Read more from Doc Palmer.

People sometimes miss two major purposes of planning. First, planning is like a manufacturing line, but instead of producing widgets, planning produces jobs ready to execute (WSch, or jobs that can be scheduled). Beware of any “backlog management” that wants a certain amount of unplanned backlog. We do not want unplanned jobs sitting around. The Planners cannot merely be busy planning work. They must finish planning work. Otherwise, we risk having to execute unplanned work because proper scheduling soon empties WSch backlogs. Management monitors any unplanned backlog encouraging Planners to use “excuse” statuses such as waiting for parts or management of change for why the work cannot move to WSch status. (Note that most PMs should come out as WSch without needing Planner attention.)

Second, and in support of quick planning, Planners run a Deming Cycle of continuous improvement. They accept that “no one is perfect” and concentrate on giving the best head start they can in the time available. In fact, the time constraint mandates that it is better to plan more of the work imperfectly than less of the work “perfectly.” Embracing the Deming Cycle, Planners plan as much detail as possible subject to the constraint that they need to plan nearly all of the work.

Other workflow cautions are noteworthy:

- First of all, the task of the Supervisors of any Requester is not to rubber stamp or write work requests themselves. It is to train their subordinates to write good work requests. Charles Kettering famously said “A problem well stated is a problem half solved.”1 Make it easy for Requesters to enter work requests and encourage them to give as much detail as possible.

- Second, be cautious with morning meetings tying up Supervisor time. These meetings should be 10 or 15 minutes, letting Supervisors know what is going on and calling attention to urgent work if necessary. A Gatekeeper with an operations background helps properly assess if requests are truly urgent. Gatekeepers can help adjust priorities without unnecessary meetings.

- Third, Operations needs some advance notice for any desired testing when Craftspersons finish work. A heads-up as any particular job nears completion allows Operations to be available for testing while the Craftsperson is still present with tools available.

- Finally, just as the Requester Supervisor should help train Requesters to write good work requests, the Craft Supervisor must help train Craftspersons to write good feedback after work execution. Supervisors must insist on good requests and good feedback.

Note how critical it is to use individual work orders for all work requests and work orders. We cannot achieve efficient or effective control over maintenance in a workflow using standing work orders such as “Yearly boiler work” or “Common equipment mechanical work.” Using individual work orders allows us to keep track of the work and sort it by urgency, asset, and system. It allows attaching job plans, selecting work to schedule, and entering job execution feedback. It also allows seeing how we are doing so we can control and improve our maintenance performance.

Addressing emergency Priority 0 work, we see that it should directly enter execution. We especially want a work order for such work. We must document emergency work to determine if we are getting better over the years by reducing emergencies. We want to document the repairs such as what parts were used for helpful history. We also want to facilitate any root cause analysis. And while Planners generally do not help jobs-in-progress, they are certainly available for data research to help emergency work.

Addressing urgent Priority 1 work, do not let this work simply bypass planning. Because Planners do not have to be perfect, they can indeed plan some of the urgent work. The key is for the Planner to check with the Craft Supervisor. If the Supervisor even thinks the crew will start the new urgent job today, DO NOT plan that work. However, if it looks like the Supervisor will not start it today, the Planner can quickly try to plan the work. There might already be a great plan in the files or CMMS. If not, simply specifying craft and labor hours and perhaps clarifying the job scope might be a great help. In this manner, we are running the Deming Cycle on some of the reactive work. Better yet, some of that “urgent” work ends up not starting this week after all. So now with its quick job plan, we can schedule that work for next week.

Pay attention to the workflow at your place. Don’t settle for good. Be great!

(1) https://www.brainyquote.com/quotes/charles_kettering_181210 accessed October 26, 2023

About the Author

Doc Palmer

PE, MBA, CMRP

Doc Palmer, PE (Ret.), MBA, CMRP is the author of McGraw-Hill’s Maintenance Planning and Scheduling Handbook and as managing partner of Richard Palmer and Associates helps companies worldwide with planning and scheduling success. For more information including online help and currently scheduled public workshops, visit www.palmerplanning.com or email Doc at [email protected]. Also visit and subscribe to www.YouTube.com/@docpalmerplanning.