Frank, the maintenance manager, had a request from the plant manager to explain why the site’s preventive maintenance compliance was averaging only 54%. Frank knew that PMs were often pushed aside by emergency work jobs, and, he reasoned, several of the PMs were obsolete or overscheduled. If they didn’t get all of the PMs done this month, there was always next month. Frank hoped that explanation would suffice for the boss.

But regardless of whether the boss accepted the explanation, Frank shouldn’t be in the position of having to come up with excuses to attempt to explain suboptimal PM compliance. In this article, we’ll take a closer look at PM compliance and how to avoid those difficult plant manager questions.

Why is PM compliance so important?

PMs prevent the need for more-intensive maintenance—or, rather, they delay failure. For example, automobile oil changes are simple PMs designed for engine reliability and longevity. Engine failure from wear doesn’t disappear with oil changes, but it can be significantly delayed.

In addition, PMs performed at plants give the mechanic an opportunity to look for other potential failures and correct them before they become catastrophic and cause extensive collateral damage. While equipment manufacturers recommend certain PMs, plants decide how often they are performed and what components are included. This decision can have a negative effect.

If a plant has a serious accident or an EPA violation, one of the first things government inspectors will examine is the PM program and compliance. After all, the plant initiated the PMs, and the plant at one time decided that the action was both important and necessary every “X” days or months on a repeating basis. A nonexistent PM may not prevent government punishment and fines, but a PM that was originated by the plant and not performed will be far worse. Such a lack of action clearly says, “I planned for this important task to be completed at X frequency, but I chose as a plant to not do it.” Many times, we see where a serious incident report by a government agency includes a statement such as, “The plant’s procedures and policies were not adhered to”—a very condemning statement for which there is no recourse.

How to clean up a PM program

Frank’s opening statement that not all the PMs were relevant and their established frequency was too high is really quite probable. Equipment and process changes, newer lubricants, and life-of-equipment enhancements often cause existing PMs to require a review. These questionable PMs need to be identified and adjusted based on experience, craft suggestions, and engineering reviews. So: clean up your PM program and look for potential updates.

At many plants, electrical PMs can account for up to 60% of the maintenance workload. That percentage represents a significant cost dedicated to a program that may be producing marginal results or, worse, subjecting equipment and personnel safety to early failure. One suggestion is to look at your most critical equipment and perform a mean time between failure (MTBF) analysis.

If you are conducting PMs by the book on a piece of equipment that has demonstrated a less-than-satisfactory life span, something is amiss. Either the PM is not capturing the right component, not being done correctly, or not being done at all. Higher-than-necessary PM frequencies often deliver minimal improvement potential. (Changing your car’s engine oil every 500 miles may not increase the engine’s life, but it sure does add to the cost!)

The bottom line, however, is that if the PM control process says to do a PM monthly, either do it monthly or change the process. Do not expect to convince your boss or the government that it was not necessary, especially after a problem has occurred.

Managing PM tasks

The best system places PMs on the weekly schedule before any other work is scheduled. If operations select the bulk of work based on labor time available for the next week, set aside a necessary portion of time for the PMs. Should emergency work break the schedule, the emergency should take time away from the scheduled routine work and not from the PM time allotments.

Plants serious about PM compliance may even authorize overtime so that scheduled PMs are accomplished regardless of extenuating circumstances that arise. Other plants may shift routine jobs to contractors in order to ensure that PM compliance is met. (After the Deepwater Horizon incident, BP established a very rigid PM compliance program.) Plants that correctly regulate PMs allow only minor repairs to be made during a PM. For major finds, new repair work orders are written so that the remaining PMs do not lose time for a PM-generated repair.

At some locations, dedicated PM mechanics do all PMs fence-to-fence and are not unit-bound. As such, they are relatively immune from being taken off PM work by an emergency job. In addition, the caliber of these mechanics and their dedication to preventive maintenance is superior as compared with a general crew that receives random PM assignments.

Tracking PM compliance

The rules recommend that PMs be completed on time. But what is “on time?” Generally, PM compliance uses the one-step-down rule. If a PM is weekly, it uses a due-by-day measurement. If it is a monthly PM, the due date ranges over a seven-day week. Quarterlies are given two weeks, and semi-annual or annual PMs are given a month to complete and be in compliance.

Glyn Thorman has 25 years of experience in maintenance and reliability consulting. He has implemented PM compliance programs and work process improvements at numerous facilities. Contact him at [email protected].

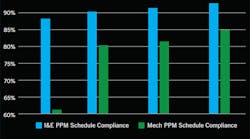

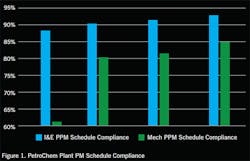

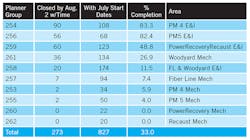

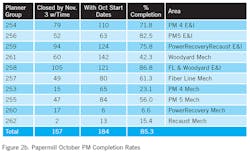

Avoid having your CMMS generate a new PM until after the previous one is marked complete. This “kicking-the-can-down-the-road” syndrome can easily change a monthly PM into a quarterly PM over the course of a year. Your CMMS should issue a new PM on a fixed basis. Tardy PMs should be closed if they continue into another period. (To avoid counting these closed work orders as done to compliance, close the open PM the day after the deadline and scrub out closed PMs with no labor hours from the list.) Hardline PM compliance demands that the PM be completed by the due date and not a day later. Figures 1 and 2 provide examples of four-month PM compliance improvement efforts, the former at a petrochem plant and the latter at a paper mill.

For those plants dedicated to PM compliance, the rule is a 90%-plus compliance with strict due dates. PMs are routinely reviewed routinely for relevance and are revised as necessary. Craftspersons are often hand-selected for the role and given the latest in training and tools. Overtime hours and contractors are used when required to meet PM compliance goals. The cost of labor for PMs is closely watched, and PMs that are not contributing to plant reliability are targeted for adjustments or removal.

PM compliance may well be your most important KPI, and it deserves careful management.