PdM in the medical field: What manufacturers can learn from medicine

[javascriptSnippet]

Is predictive maintenance more of a hobby than a way of life at your plant? Most plants I visit do very little in the way of PdM diagnostics – usually, it represents about 1%-2% of total available craft labor hours. Corrective follow-up work from PdM diagnostics may receive similarly little attention, and most plants don’t track their corrective follow-up work. The plant I was associated with for my 35-year career had about 1% PdM diagnostics and did very little corrective follow-up work from its PdM finds. All of that changed around 2006. That’s when our knowledge on the power of the PF curve hit the tipping point.

In 2006, my facility was achieving very good reliability and maintenance cost savings from our focus on planned-scheduled-kitted work. We began reinvesting our repair and maintenance (R&M) savings in our PdM crew and built the crew to eight full-time PdM specialists. These guys were seasoned electricians and general mechanics who stepped forward with a strong interest in the PdM specialty. We increased our PdM diagnostic level to 8% with an additional 6% of labor hours performing PdM corrective follow-up work.

We identified almost 500 PdM anomalies annually that were advanced to planned-scheduled-kitted corrective follow-up repairs. That’s 10 “ticking bombs” that were disarmed each week at a fraction of the cost that we would have seen had we let each anomaly proceed to failure. We operated at this level for many years, and it saved our plants millions of dollars in R&M costs and increased our equipment uptime.

I’ve seen the PF curve illustrated many different ways. The constant is the recommendation that PdM diagnostics be 15% with 35% PdM corrective follow-up work. Also constant is the recommendation that PM diagnostics be 15% with 15% preventive maintenance (PM) corrective follow-up work. Again, the best we achieved at the plant where I was the lean manufacturing manager and reliability excellence facilitator was a combined 14% for our PdM efforts, and we achieved significant cost savings. We always wondered whether any industry really achieved the elusive 50% combined effort with PdM. Was it truly attainable or simply a hypothetical target? There was agreement in our management group that if we or anyone else could ever get to the 50% level, the payoff would be grand.

In fact, there is an industry that operates at the combined 50% level (at least): the medical industry, which operates today with a tremendous amount of PdM diagnosis and corrective action.

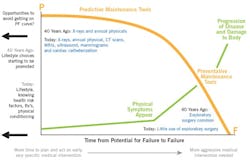

The PF curve as applied to the medical field can be creatively illustrated, as in the accompanying chart. The premise of the PF curve in the medical world is that the human body will provide early warning signals and detection opportunities to discover illnesses. Likewise, illnesses can progress down the PF curve in weeks, months, or years – the same as for machinery. One noteworthy observation is that the human body has the ability to cure itself of many illnesses. However, once an anomaly or defect appears on the PF curve for a machine, it’s just a matter of time before that machine will fail. Machines cannot repair themselves.

Is there PF curve thinking in the medical field?

Let’s revisit the approach the medical industry used 40 years ago. Radiologic technology alone was set high on the PF curve as the primary method available for early detection of illness. Annual physical exams with tests certainly were also helpful in surfacing illness symptoms that might not be visibly apparent. Another medical procedure used to better understand a person’s illness was exploratory surgery. Exploratory surgery often resulted in a corrective procedure, but the surgery itself was invasive and guaranteed a hospital stay and the potential for surgical complications such as infection, blood clots, and pneumonia.

For the PF curve illustration, an exploratory surgery isn’t a PdM technology. It’s more similar to the modern-day PMs we perform on machinery as we inspect, adjust, and troubleshoot machine components. Machine PMs, like exploratory surgery on the human body, could result in the introduction of additional anomalies.

Now let’s talk about the PdM-type technologies the medical industry currently uses. Medical PdM technologies include X-rays, CT scans, MRIs, ultrasound, mammograms, and cardiac catheterization. All of these PdM technologies are set high on the PF curve looking for signs of illness very early, and the result is often a very specific medical intervention.

These predictive medical tools commonly identify other medical needs indirectly. We all know friends and relatives who had a surgery that involved no external stitches. The PdM medical technology told the surgeon exactly where the anomaly was located in the body. Hospital stays can be shorter. Perhaps an open-heart surgery was avoided because a stent was set via arterial catheterization. One rarely hears the term exploratory surgery today because it’s been mostly replaced by medical procedures high up on the PF curve. Is the medical industry at a 50% combined level of PdM diagnostic and follow-up corrective action level? The actual percentages would be difficult to determine. Certainly the percentage is high and many, many lives are being saved.

It’s also noteworthy to point out that there is tremendous effort put forth to help people minimize the chances of their body getting on the PF curve with some anomaly. The medical field promotes awareness that a person’s lifestyle, knowledge of health risk factors, prescribed medicines, and physical conditioning all can affect health in a positive way.

Embracing a predictive approach

So here’s the question: Which medical treatment approach would you prefer for your family? Today’s approach or the approach used 40 years ago? Certainly most would choose today’s approach and think it silly that the question even be asked.

Let’s ask the question in a different way. Are we performing R&M in our plants the way the medical field operated 40 years ago? Or are we performing R&M like today’s medical field operates, with advanced diagnostic technologies and early interventions?

Unfortunately, most manufacturing and heavy industry in the United States still relies on the decades-old approach. Those of us who work in these industries depend on them for our paychecks and long-term job security that will enable us to take care of our families as best we can. So why wouldn’t we want to embrace PdM thinking like today’s medical field does? Keeping our manufacturing and heavy industrial base healthy is good for everyone in our communities and our country.

Reliability engineers are probably the most knowledgeable about PdM technologies and their application. If you are a reliability engineer working in a plant that operates at a 1%–2% PdM diagnostic level and you’re frustrated the percentage of PdM is not higher, then show this article to your plant manager and ask him or her to sponsor your efforts to increase PdM diagnostic and corrective follow-up repair activity. If your plant doesn’t have a reliability engineer, then hiring one might be your best first step.

Cassie Keneipp is recently retired as a board-certified radiologic technologist at Deaconess Hospital in Evansville, IN, where she worked for 39 years.

It’s important to note that this shift is about culture change or change management at its core. A transformation in your industry toward increased reliability excellence has a definite culture change aspect that must be part of the overall implementation plan to achieve success. Many transformations are strong on leadership, sponsorship, and project management but weak on change management. Change management is the people side of change or culture change. It’s getting people to want to use the change. The people in the organization are all wondering: Is this another program-of-the-month or is it something bigger? Imagine a company is implementing a major initiative and people throughout the organization are thinking: “I don’t care if this happens or not.” That’s a very bad outcome! That’s why change management is so important.

A better outcome will be people saying: “I understand the change and why we’re doing it. It will be a good deal for all of us and I’d like to be a part of it.” Change management affects speed of adoption, ultimate use of the change, proficiency, and a sustained return on investment.