Organizations invest millions of dollars each year in information management software solutions to manage their information requirements and documents pertaining to their asset management strategy. The newly released ISO 55002, Asset management — Management systems — Guidelines for the application of ISO 55001, defines this information technology as support to the asset management system. The information requirements contained within this standard outline the gaps that routinely prevent the realization of the return defined in the business case that was used in selecting the software package. Here are six common mistakes organizations make that prevent their investment from yielding the predicted benefits.

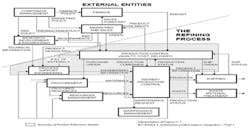

1. Value stream: Despite the traction that lean principles have gained in manufacturing, there’s still a significant weakness in organizations inside and outside of manufacturing because they fail to define the value stream and how the human assets and physical assets come together to create value for the organization. Without this, the complexity of information management becomes overwhelming. Take the example in Figure 1, an interpretation from IEC 62264-1, of the information flow for a refinery.

Figure 1. This information flow for a refinery, an interpretation from IEC 62264-1, makes it easy to define which data and requirements are necessary for the management of information relating to the assets and how they create value for the business.

Once this information flow is clearly understood, it’s easier to define which data and requirements are necessary for the management of information relating to the assets and how they create value for the business. Without this transparent linkage to the business, it’s nearly impossible for an organization to configure a system to leverage information to make real-time asset management decisions.

2. Business processes: A lack of clearly defined business processes at the transaction level creates a significant amount of non-value-added work for an organization by allowing significant variation in the management systems. Another weakness is poorly defined roles and responsibilities for the execution of each step within the processes. Investing in technology without the process and systems alignment can actually reduce profitability due to an increase in non-value-added work such as time spent data mining, duplication of databases, duplication of information systems, and ad hoc workarounds. Without clearly defined business processes, it’s difficult to outline the functional requirements that need to be met for an effective asset management strategy.

3. User requirements: The individuals who design, acquire, construct, commission, operate, maintain, and dispose of the company’s physical asset portfolio have specific functional requirements and the resultant data, shown in Figure 2, that are needed to manage these assets throughout the lifecycle. A significant number of these requirements reside in the information technology domain. Unfortunately, the selection, configuration, and implementation of solutions to meet the functional requirements are often conducted by a group of individuals with limited understanding of those requirements, and communication across the white space is all but nonexistent. An absence of management commitment and a lack of internal partnership agreements often combine to prevent this necessary collaboration. These user requirements should be linked to business objectives and reinforced by metrics that drive the right behavior.

Figure 2. The individuals who design, acquire, construct, commission, operate, maintain, and dispose of the company’s physical asset portfolio have specific functional requirements and the resultant data that are needed to manage these assets throughout the lifecycle.

4. Master data: Another area of opportunity is the master data contained within the EAM system. Most IT-centric implementations fail to realize that installing the software on the servers or hosting the software in the cloud is a fraction of the level of effort and cost in configuring and implementing to support asset management best practices. Data integrity is important due to business, legal, and regulatory requirements. The controls put in place should be adequate for the type of information in supporting the asset management activity, according to ISO 55002:2014, Section 7.6, Documented Information. In more than 300 assessments that we’ve conducted over the past several decades, less than 30% of the data was accurate in the electronic-to-field audits. Such poor data integrity is usually due to a weak initial implementation plan, lack of management of change, obsolescence, and loose procurement controls.

The classifications of asset types, with clear definitions and a standard naming convention, should be adopted by the organization as a whole. These asset types and other criteria which distinguish these assets, such as lifecycle cost, end of life, asset replacement value, engineering specifications, and reliability data, provide the foundation for analytics. Typically, this classification doesn’t exist, due to a poor initial implementation plan, lack of management of change, obsolescence, and slack procurement controls.

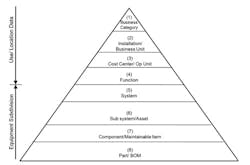

5. Hierarchical structure: Taxonomy is defined by ISO 14224:2006 as a systematic classification of items into generic groups based on factors possibly common to several of the items — for example, location, use, or equipment subdivision. A classification of relevant data to be collected by this international standard is represented by a hierarchy shown in Figure 3.

Figure 3. Taxonomy is defined by ISO 14224:2006 as a systematic classification of items into generic groups based on factors possibly common to several of the items.

Since most hierarchical structures are defined in an EAM system as a function of general ledgers and balance sheets, there is very little effort invested in this structure below Level 4. Unfortunately, levels 5-8 are the ones that provide the granularity to collect relevant failure modes, effects, and causes, along with detection methods for applying RCM analysis and conducting root cause analysis for identifying risks and also evaluating the effectiveness of control strategies. The lack of detail within these levels is an impediment to performing reliability analytics.

Mike Poland, CMRP, is director of Life Cycle Engineering’s Asset Management Services group. With more than 25 years of engineering and maintenance experience, Poland specializes in reliability processes and systems engineering with an emphasis on defect detection and elimination through root cause analysis and risk-based inspections. His approach to risk-based asset management and the elimination of limiting factors for clients provides greatly enhanced asset utilization at a much lower total cost of ownership. Contact him at [email protected].

6. Metrics: With any management system, there needs to be a way to close the loop. All management systems that are developed per ISO 72:2001, Guidelines for the justification and development of Management System Standards, will be developed in a plan-do-check-act continuous improvement cycle. Without metrics, there is no “check” portion of the cycle, and therefore improvement is lacking. The five items prior to this final critical success factor — value stream, business processes, user requirements, master data, and hierarchical structure — are fundamental for metric development and application. The overarching principal for a metric is to ensure it drives the right behavior. A metric must have a definition, objectives, formula for calculating, source of data for each term in the calculation, time basis, desired behavior the metric will drive, and target values to strive for.

Overlooking or failing to invest the proper level of effort in configuring and implementing your enterprise asset management system to ensure these six factors are adequately addressed will yield sub-optimized asset management that will prevent higher asset utilization at a lower total cost of ownership. This is why you have failed to achieve your return on investment in what was sold as an enabling technology but only resulted in frustration by the users and continued incremental cost in workarounds and stopgap measures. Read and understand the international standards, then self-assess, define your gaps, and develop your action plan and milestones to improve and finally achieve the ROI that your business’ bottom line demands.