2025 electrical safety survey reveals top risks for manufacturing facilities

Key takeaways

- Younger workers are entering the field fast, but many lack key technical certifications.

- Poor maintenance and training remain top threats to electrical safety on plant floors.

- Smart tools are gaining traction, with 70% seeing them as a boost to safety and efficiency.

- Many plants have near-miss plans, but only two-thirds use formal reporting systems.

Do you consider your plant electrically up to code? What are the electrical safety challenges at your facility? And, in a moment where the potential of AI has caught everyone’s attention, how interested are you in using smart tools to improve safety?

These were the key questions posed in the 2025 Plant Services Electrical Safety Survey. This is the third time Plant Services has run the survey with our readers (see 2018 article "Is your plant a safe plant?" and 2020 article "Red alert"), and more than 150 industry professionals provided their feedback in January and February of this year for the 2025 survey.

The 23-question survey included topics such as training and certifications, time between electrical incidents, and near-miss reporting, as well as asking what kinds of tools and PPE are currently being used. Also, this survey asked a few new questions about smart tools – devices that collect and process data in real-time and provide actionable insights – to get a sense of what the market reality is for these devices.

This article presents highlights and key findings. Click here to access the full survey report, and click here to download the full 23-question data set.

A growing gap: New hires lack experience, veterans pursue advanced training

The first interesting data points emerged from the short series of demographic questions that we’ve asked on all three Electrical Safety surveys. This year, the questions on length of experience and number of certifications earned reveal a certain greening of the workforce. For example, the number of 2025 survey respondents with 5 years or less experience increased by almost 70% from when we ran this survey in 2020, even as the largest segment of respondents remained those who have at least 16 years of experience.

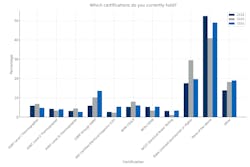

The next question asked about the types of professional certifications held by respondents. Compared to data from the 2020 survey, the numbers went up for key higher-level certifications, including the CMRP, CEI, and CESW. However, those selecting “none of the above” also increased from 2020, up from 40.9% to 49.0% (see Figure 1).

Taken together, these data indicate that a segment of 2025 respondents has not been in industry long enough to earn or pursue key technical certifications; and, that those who have more experience also have not slowed their pursuit of continuing education and training.

Key electrical safety challenges

The next set of survey questions asked respondents about the electrical safety challenges that they find most pressing at their facilities. Four safety challenges stood out for 2025: poor/ineffective equipment maintenance (37.0%), poor/ineffective training (36.6%), poor/ineffective incident reporting (23.5%), and slips, trips, falls (22.9%).

The series of follow-up questions added depth to those core findings:

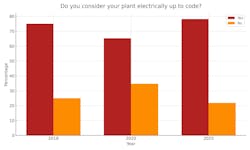

- More than 78% of respondents thought their facility was up to code, the highest level of the past seven years (see Figure 2).

- Overall, the average time between electrical incidents is increasing, with almost 50% of respondents saying it has been more than a year between incidents.

- Although the number of respondents saying they have been part of an OSHA investigation has increased steadily since 2018 to 37.2% currently, the number of respondents either involved in arc flash incidents who know someone involved has decreased from 60% to 52%.

- When it comes to training, it is a tale of the haves and have-nots: the number of people saying they were trained up to the latest version of NFPA 70E increased since 2020 to 17.7%; however, the number of people who say they have not been trained at all on NFPA 70E also increased in 2025 to 47.8%.

- When it comes to incident reporting, 89% of respondents say there is a near-miss reporting plan in place at their facility, but only 2 in 3 of those programs are formal reporting programs.

Smart tech gains momentum as outsourcing remains steady

The last section of the survey asked about people’s attitudes toward both tools of the trade, especially smart tools, as well as the kinds of electrical work that are commonly contracted out.

The percentage of respondents who do contract out certain types of work (installation [71.9%], testing [67.0%], repairs [67.9%], and condition monitoring [37.3%]) stayed generally consistent with past results, with only testing work showing a clear increase from 2020 data.

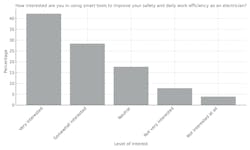

On smart tools – devices that collect and process data in real-time and provide actionable insights – survey respondents signaled a strong interest in the potential for these tools to improve safety and work efficiency. Just over 60% of respondents said they were interested in applying these tools, with almost 70% saying they thought these tools would improve electrical safety (see Figures 3 and 4). Nearly as many also thought smart tools would increase job efficiency and productivity, as well as accuracy and troubleshooting.

The final question asked about planned technology investments to enhance electrical safety, so it is worth noting that responses were collected before the Trump administration announced their tariff strategy. Of the safety technologies listed, the most-deployed technologies are switches (both limit and interlock), single-function relays, PLCs, and overcurrent protection devices. The devices coming in at the bottom of the list are IR windows and viewports and motion control devices.

Want to learn more? Download the full 2025 Electrical Survey report, and the full 23-question data set.

About the Author

Thomas Wilk

editor in chief

Thomas Wilk joined Plant Services as editor in chief in 2014. Previously, Wilk was content strategist / mobile media manager at Panduit. Prior to Panduit, Tom was lead editor for Battelle Memorial Institute's Environmental Restoration team, and taught business and technical writing at Ohio State University for eight years. Tom holds a BA from the University of Illinois and an MA from Ohio State University