Safety tips for CNC machinery operation

CNC vertical machining centers are regarded as some of the most versatile machinery used by leading manufacturing firms. These machines have vertically oriented cylindrical cutters on a spindle axis (see Figure 1).

CNC enables some vertical machining centers to get manipulated on up to five axes to perform the fabrication of desirable shapes, holes, slots, and refined details in three-dimensional components.

CNC vertical machining centers can deliver high precision and mass production requirements and are thus ideal for industries including automobile, aerospace, textile, instrumentation, mold making, military components, and several others.

Vertical machining center hazards

When operating a CNC vertical machine, machinists must be aware of the dangers it poses if not handled correctly and with appropriate supervision. Some of the common vulnerabilities associated with the unsupervised use of a vertical machining center include:

- Flying debris—If the machine is not covered with guards and shields, the machinist is at critical risk of being hit by a loose tool or piece of stock that might break off during operation. Flying debris or parts can also damage machines nearby and pose life-threatening risks.

- Pull of clothing and linen in the machine—The components in a vertical machining center move at high speeds during operation and pose a risk of fatal injury to machinists or bystanders. If loose clothing comes into contact with a moving component of the machine, it will immediately get caught and pull the wearer in, leading to fatalities.

- Maintenance injuries—While maintenance is safe and harm-free, it can be fatal if the machine is not shut down fully before performing maintenance. If the machine is still under operation, it could harm the technician by grabbing their clothing or hurting them with fast-moving parts.

- Injuries related to repetitive stress—Being locked in the same body posture throughout the operation or performing a motion repeatedly, like feeding stock into the machine, can lead to ergonomic injuries. Repetitive motion-related stress can also wear out the operator and negatively impact the safety of the machinist.

Operational practices to avoid

To ensure the safety and well being of workers and the efficient operation of your CNC machine, here are some practices that you must avoid:

Overlooking minor maintenance tasks

Tool breakdowns can lead to minor errors that might not cause the machine to break down but can lead to significant damages if left uncatered. Most CNC machine errors and operational issues stem from improper maintenance and reckless usage. Therefore, you must ensure timely maintenance of the machine and have replacement equipment at your disposal to minimize downtime.

Standing next to the machine

To avoid mishaps during machining, it is advisable to maintain a certain distance from the movable parts of the CNC machine so that you do not get caught in it. Never wear baggy clothes or those with loose threads. It is also recommended to shut all doors of the machine room before operation.

Letting unskilled workers fidget with the machine

You must seek assistance from a CNC expert when altering the tool of the vertical machine since wrongly fitted screws and protective enclosures can lead to parts swinging out.

Besides that, skilled operators are aware of the settings required for different materials and thus, help prevent catastrophic failures caused by incorrect programming.

Erroneous programming of the CNC machine can lead to a fatal crash or damage the moving components, tools, spindles, and other parts.

Relying entirely on automation

Despite the levels of automation implemented in your CNC vertical machine, you must never leave it unattended. Be sure to have a supervisor in the room during the machine’s operation. Upon completion, be sure to switch it off.

CNC machinists must possess extensive knowledge of the tool operation. Besides that, the operator present also ensures optimum accuracy levels, which might fall due to the wear of the tools.

Operator tips to stay safe

So far, you have learned about the different threats posed by a vertical machining center. To help you avoid fatalities and ensure a smooth machine operation, here are some vertical machining center safety tips that you must follow to minimize the risk of injury.

Ensure proper maintenance and hygiene.

Before using your CNC vertical machining center, be sure to clean its movable parts of any dirt or oil that might cause it to malfunction. Also, be sure to visually inspect all screws and bolts of the moving components and the protective guards. Here is a checklist to perform before every operation:

- Double-check tool settings.

- Inspect for cracks and damage.

- Perform tool testing before installing the machine.

- Verify that the tool data correlates to the program.

- Keep the parts free of oil and dirt.

- Use tools within the limits set by the manufacturer.

When performing maintenance, ensure that the machine is completely shut down based on the manufacturer’s instructions. Do not hesitate to consult a trained machinist if you have any doubts.

If you run a small-scale business, go for a desktop CNC machine as it is just as efficient as the regular sized ones while costing significantly less.

Put on personal protective equipment during operation.

Machinery production must also account for user protection during the entire design process. While the machine comes with added layers of protection if a malfunction were to occur, you are never entirely safe from catastrophic collapses. Therefore, it is advisable to take the extra step of putting on PPE, which includes work shoes, hearing protection, and safety goggles.

While it might seem like a good idea to wear gloves, they pose some of the highest risks of getting caught by moving parts of the vertical machine. The clothing threads emerging from gloves often get caught in the machine and draw the operator dangerously close toward the speeding components.

Provide proper training to machinists.

A vertical machining center is not child’s play to operate and thus requires extensive training to avoid injury and ensure seamless operation with no downtime. The operator of the vertical machine must be aware of its working and potential hazards. Training should include mentioning the risks of the machine and ways to prevent them.

Do not buy into cheaper alterations.

Some tools and components of the vertical machining center are pricey, and operators feel that they should opt for affordable alternatives to stay within budget. However, almost all CNC operator’s manuals warn against it.

Cheap tools can cause releases of bursts of energy when hardened steel tooling collides with other equipment, causing the components to break through the reinforced enclosures. This scenario can lead to fatalities and damage the nearby equipment.

Let trained machinists handle safety guards.

Most accidents occur when unskilled operators try reaching inside the vertical machine to clear a blockage. It is advisable to leave this job for machinists who have received additional training in adding or removing these protective guards.

Safety guards help block sparks, debris, and loose screws from being shot out of the machine during operation. They also prevent the operator from getting caught inside the moving machine.

Promote automation in daily processes.

Processes such as CNC and automatic stock feed minimize human interaction so that they do not have to deal with the most dangerous components of the machine. Besides the safety benefits, automation can also significantly boost productivity, reduce labor costs, minimize downtime, and as a result, improve profits.

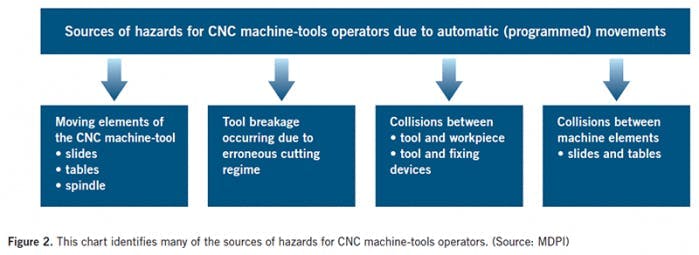

However, CNC machines must only get operated by qualified machinists. Excessive automation often drives employers to recruit minimally skilled labor not trained to perform the tedious tasks when required. This scenario can pose a threat to the operators’ safety and the streamlined functioning of the machine. Automatic or programmed movements can be sources of hazards for CNC machine-tools operators (see Figure 2).

Timely maintenance needed

A CNC vertical machining center is one of the most profitable machines in the industry that removes material from a piece to create the desired shape. Besides its long list of benefits, you must also be aware of the potential hazards that come with using this machine without caution.

It is advisable to ensure proper and timely maintenance, wear PPE equipment, provide training to operators, and automate mundane processes to minimize human intervention. If you are unaware of the machine’s working, consult trained technicians for supervision.