Breathing air purifiers protect respiratory air supplies

Industrial hygienists, plant engineers and safety managers agree that it's critical to deliver safe breathing air to the respirators, hoods and masks used in sandblasting, spray painting, tank cleaning and arc welding. This goes equally for underwater work and cleanroom applications.

The breathing air source for many process plant applications is an oil-lubricated or oil-less air compressor. Ambient air entering the compressor may contain dust, dirt, water vapor, hydrocarbon vapor and, the most dangerous, carbon monoxide from vehicle exhaust and other forms of hydrocarbon combustion. Even if the compressor is installed in an environment having clean ambient air with reduced contaminants and normal concentrations of oxygen, it still needs a purifier if the air is used for breathing.

This article summarizes the major workplace hazards, and offers guidelines for selecting compressor purifiers for breathing air systems.

Abrasive blasting

Abrasive blasting operations commonly use sand to clean iron and steel surfaces, brick, stone, concrete, sand castings, aluminum, brass, copper, wood, glass and plastic. Silica dust (SiO2) is produced when sand is used as the abrasive material. Of special concern is dust from pulverized surface coatings, encrusted materials and substrates. In terms of worker health, though, silica dust is of major concern because it may cause silicosis, a lung disease that develops slowly and often leads to death years after exposure has ceased (see Figure 1).

Figure 1. Abrasive blasting can produce silica dust, which, if inhaled, can lead to silicosis.

Paint spraying

Organic vapor and mist from paint, lacquer, enamel and solvents present an air hazard in paint-spraying operations. Disposable particle-type face masks, which afford only dust particulate protection, are commonly selected for comfort, not their ability to provide safe respiratory air.

Industrial cleaning

Tank cleaning operations involve solvents that can pose threats to worker safety. While the most common result of contact with organic solvents is dermatitis (inflammation of the skin), inhaling solvent vapors can have grave effects on the central nervous system. Trichlorethylene and perchloroethylene, two of the more toxic solvents, have been used extensively in metal and equipment vapor-degreasing operations, but many plants have moved to less toxic substances. Known effects of exposure to these solvents include dizziness, headaches, lack of coordination and central nervous system depression.

Arc welding

Arc welding generates metal fumes and gases that cause health concerns: Ozone, an intensely irritating gas, and oxides of nitrogen are the principal bad actors. Other contaminants may arise from oxides of the welding rod components, alloying elements and the metal being joined. In addition, some paints may produce toxic fumes when heated. Other toxic fumes are generated when welded metals contain, or are coated with, alloys of lead, zinc, cadmium or beryllium, each of which is capable of producing metal fume fever. Symptoms usually occur a few hours after exposure and are similar to those of influenza: a metallic taste in the mouth, dryness of the nose and throat, weakness, fatigue, muscular and joint pain, fever, chills and nausea. The symptoms usually last less than 24 hours, followed by a temporary immunity, which explains why welders are more susceptible on Mondays and workdays following a holiday.

Carbon monoxide removal

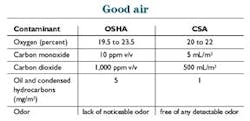

The ability to remove carbon monoxide gives respiratory air users peace of mind. A catalyst in a compressed air purifier converts carbon monoxide to carbon dioxide. Because catalyst conversion efficiency decreases as relative humidity increases, the purifier limits moisture content with a prefilter and desiccant dryer. Following the catalyst, activated carbon filters remove odor and hydrocarbon vapors. A final particulate filter removes desiccant dust and other fines. Carbon monoxide analyzers with remote alarms and monitoring are excellent options. Such purifiers provide 95 percent carbon monoxide conversion efficiency, reducing the concentration to the 10-ppm maximum that OSHA specifies (see Table 1).

Table 1. Contaminant and maximum allowable limit required by OSHA in the U.S. and CSA in Canada.

Purifier selection

Purifiers are available for continuous and non-continuous applications. For periodic respiratory air usage, cart-mounted purifiers with disposable cartridges can serve highly intermittent and highly mobile applications.

Workers involved with abrasive blasting, paint spraying, industrial cleaning and arc welding must be protected from air-borne particulates and other air contaminants. Providing purified breathing air is the minimum measure that every plant should have available for the purpose.

Rod Smith is vice president of Sales and Marketing, SPX Air Treatment in Canonsburg, Pa. He can be reached at [email protected] and 724-746-4240 x 283.