The industrial internet of things (IIoT) has started to become much more than just a buzzphrase. In the last couple of years, IIoT systems have been increasingly deployed in factory environments to monitor critical equipment. As plants have started to understand the value of continuous monitoring and analysis of critical equipment, they have begun to invest in IIoT systems specifically for predictive maintenance (PdM).

It is generally not enough to simply install sensors and collect large amounts of data. The assets to be monitored, the locations of the sensors, and the data collection methods and frequency are all very important aspects to be considered. Integration of the IIoT system into an overall preventive maintenance (PM) or PdM strategy is also necessary.

This article discusses these and other practical aspects of deploying an IIoT system. Use cases are presented to illustrate the benefits of deploying IIoT systems on the plant floor.

Practical aspects of IIoT deployment

Observing the following practical aspects of IIoT deployment will help get you and your teams started on the right path.

Monitor critical assets first. As a first step, it is very useful to perform an audit of the manufacturing operation to help identify the critical assets. The result of the equipment audit should be a list of all major assets in a facility ranked by criticality. Note that the list should break assemblies/powertrains down into the repairable or replaceable components that make up the larger machine.

The main purpose of a PdM system in most cases is to avoid unexpected equipment failure to minimize plant downtime. Therefore, the cost of a motor or pump or compressor that is being monitored is typically not as important as the function it performs in the manufacturing process. A cost per hour for each area of the operation or each process will be very helpful as well as an overall cost per hour for the entire facility. Those figures will be used in ROI calculations when creating your PdM strategy.

Simply deploying sensors and collecting vast amounts of data is not enough. Because of the ease of use of cloud-based platforms, it is very tempting to collect data as often as possible “just in case.” Managing and interpreting the large amounts of data collected can become a very difficult and costly task. It is therefore important to only collect relevant data to perform the required analysis. One may start with collecting data at a high rate and then once the system behavior is understood, reduce the rate to a level that is enough to perform the required analysis.

As an example, in a fixed speed motor application, after initial baseline data are collected, it may suffice to collect data a few times a day until an anomaly is observed. At that point, the data collection rate can be increased as required. Fortunately, there are cloud-based IIoT systems that make this process very simple.

Wireless solutions are much easier and often less costly to deploy compared to traditional wired solutions. You want to avoid cables around vibrating and rotating equipment for obvious reasons. Wireless sensors are battery powered and with advances in sensing technology, communication protocols, and energy management, batteries typically last several years.

Start small, and deploy the minimal set of sensors needed to do the job. Select a critical asset to monitor and deploy a few sensors to gain experience and build a use case. Not only does this lower the initial cost of deployment, it also helps minimize the amount of data collected. These days, multi-function sensors are available (e.g., sensors that measure multiple axes of vibration and temperature at more than one location) that help optimize the number of sensors needed. Once a viable use case has been established, it is usually straightforward to scale up by deploying additional sensors onto other critical assets.

Cloud-based systems provide the flexibility of performing PdM without relying on plant IT infrastructure. There are several ways to get the data in to the cloud system, such as cellular, plant internal network (e.g., Ethernet or WiFi), and external internet access (e.g., independent ISP). Integrating into the plant network is often frowned upon owing to stringent IT security policies. The cost of external internet access must be included in the total cost of ownership (TCO) of an IIoT system. Cellular providers typically have special data plans for machine-to-machine communication that are considerably more cost-effective than standard cellular data plans.

You need to act on the data. Once data has been collected for some time and a baseline has been established, rules can be created as needed to alert the maintenance personnel of anomalies in the assets being monitored. It is important to take appropriate action when an alert is triggered (e.g., lubricate or replace a bearing, perform alignment, etc.). Accepting and acting on insights derived from PdM technology can be a significant cultural change for maintenance and reliability veterans. It is no small task to challenge established practices such as time-based maintenance and make the switch to a condition-based approach. In order to make this transition successful, everyone must buy in to the idea that insights are valid, and the proof is stacking up in favor of predictive maintenance.

Example applications

A properly deployed and acted upon IIoT system for PdM can provide great benefits. Consider a case where an IIoT system was deployed in an outdoor rock-crushing operation during winter. This plant had experienced several unexpected failures of critical motors and gearboxes driving a conveyer belt, leading to a complete plant shutdown for days. Sensors measuring vibration and temperature were deployed on the critical motors, bearings, and gearboxes. To minimize the costs and the amount of data collected on the motor, only the drive end bearings were monitored. An initial data collection rate of once an hour was implemented.

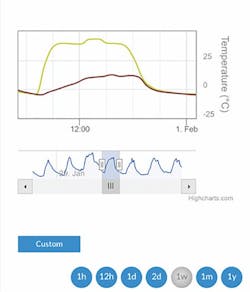

A review of the baseline data collected after just a few days indicated that the daily temperature variation (Figure 1) of one of the gearboxes (left side of the conveyer belt) was much greater than that of another identical gearbox (right side of the conveyer belt). The data clearly indicated that there was unbalanced loading in the system and that the gearbox with the higher temperature was likely to fail soon.

Figure 1. Temperature measurement on gearboxes (yellow - left gearbox, brown - right gearbox). (Source: Nidec)

The IIoT system alerted plant maintenance and provided the necessary insights into the root cause. The steady increase in temperature over time provided the plant with foresight into the rate of deterioration and expected life of the gearbox. As a result, they were able to purchase a spare gearbox in time at a reasonable cost (no rush charges), and when the overloaded gearbox failed, were able to replace it and correct the issue within two hours, leading to avoidance of lengthy downtime.

Another interesting use case involved the use of a multi-function sensor in an aluminum die-cast line. The critical equipment monitored was a motor-pump combination that had failed several times and required frequent replacement. Sensors were placed on the drive ends of the motor and the pump. Based on the history and criticality of this equipment, measurements were taken every 10 minutes to establish an initial baseline.

Figure 2 shows overall vibration and temperature trending (top graph). The dark blue line represents the surface temperature of the pump drive end, and the light blue curve is the overall vibration level in vertical direction. Further below, the corresponding vibration data in frequency and time domain are shown.

Figure 2. Trending and spectral data of pump vibration and temperature. (Source: Nidec)

The IIoT system alerted plant maintenance of a developing issue, as analysis of the data showed a progressively deteriorating pump bearing. A potential impact caused by a change in process or environmental conditions was ruled out based on a consistent temperature profile. The maintenance team in the plant simply changed the lubricant, which allowed operations to continue without extended downtime.

In both cases, plant maintenance clearly identified the critical assets and then used the optimal number and type of sensors and data collection intervals to remotely monitor the health condition. This allowed them to pinpoint problems and proactively take appropriate action resulting in considerable cost avoidance. Clearly, a suitably deployed IIoT system is a powerful ally in the fight against unplanned and costly downtime!

Create a long-term strategy

Finally, as PdM solutions become more prevalent, it is important to create a long-term strategy for leveraging technology without allowing individual/point solutions to become siloed. Industrial equipment manufacturers have developed solutions to monitor the equipment they manufacture. In addition, several sensor and software companies offer versions of PdM solutions which are often equipment agnostic.

The good news is that there are software platforms being developed that address the need to integrate multiple IIoT solutions. Further, cloud-based technologies are accelerating the capabilities of providers to create predictive maintenance platforms using standardized security protocols and IT services which multiple stakeholders can leverage. The entire industrial supply chain can benefit from machine health and performance insights generated at the plant floor level.

Forward-thinking organizations are making the strategic partnerships necessary to maximize the productivity and efficiency of their plants by equipping their maintenance and reliability teams with PdM technology solutions.

Thomas Schardt is Nidec Motor Corporation’s VP of digitalization, strategy, and innovation. He is responsible for leading digital transformation strategy by implementing new digital technologies and business innovations, including responsibility for the IIoT strategy and infrastructure development to grow Nidec Motor’s equipment monitoring platform.

Pranesh Rao is director of new products, electronics and software for Nidec Motor Corporation. In this role, he is responsible for the development of Nidec Motor Corporation’s integrated motor drives and IIoT platforms.

Justin Lesley is Industry 4.0 innovation manager at Motion Industries, directing IIoT strategy and partnerships related to the MRO industry. His career centers on operational efficiency supported by his Lean manufacturing and Six Sigma certifications combined with his engineering credentials. For more information, visit MotionIndustries.com/plantservices, or TheMotorSpecialist.com.