Building the business case for training and development investment

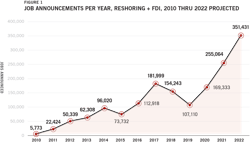

In spite of a threatening economic recession, many key outlets indicate a resurgence of industrial manufacturing back to the United States. The weaknesses in a lean global supply chain that were exposed during the pandemic are slowly being dealt with. The latest data from the Reshoring Initiative show that reshoring jobs plus increases in foreign domestic investment are 15% above the first quarter of 2022, which is the highest rate ever recorded (see Figure 1).

With new manufacturing jobs coming back to the U.S., some industry sectors are facing layoffs and cutbacks. So, if you’re in a situation where you’re faced with doing more with less, at least ensure that your staff is trained up to their expected ability. If the work that they are to perform is held to a certain standard, then the instructions and procedures that they are given should be written to the same standard. Proper training, combined with thorough work instructions and procedures, can help drive the effectiveness and efficiency of your maintenance and reliability team.

Building a business case

If you’re trying to sell the need for additional training to your decision makers, it may help to create a business case. A business case is really just a form of a gap analysis. It should describe (1) your issue, (2) the current status, and (3) the desired results. The results desired should be centered around your organization’s goals and objectives: how reliability will be improved, if there are any safety issues that can be avoided because of having the training, and how any possible product and efficiency improvements can be gained.

Your problem statement should be concise and specific, keeping to no more than one paragraph. For background information, include specific information regarding cost and budgeting, as well as what would be required to resolve the skills deficiency that the training will address. Also describe the current situation, and again mention specifics such as results from a skills gap analysis, or a change in equipment or assets where needed skills and experience will help to maintain and troubleshoot the new equipment. Consider using metrics such as Mean Time To Repair (MTTR) as a way to identify what skills or training may be necessary.

For estimating costs for budgeting purposes, consider using the Maintenance Training Cost metric, which is commonly represented as a percentage of the employee’s annual wage. The metric was developed to determine what the industry standard is for how much training maintenance employees are to receive per year. Since this metric varies due to annual wage, the range can be between 1.65% to 4.4%. Another possible metric to use is training hours per maintenance employee, and best-in-class is 80 hours per employee per year.

Ensure that you have stated your current process, and how current processes and lack of skills needed is affecting any production, reliability, or even quality related issues. List any requirements and resources that will be needed for the training. If there’s one thing that the pandemic pushed forward, it’s online training. Many vendors pivoted to online training, and there are some very nicely done online training options available now, that are both interactive and blended with a live instructor. However, if online training is not an option, be sure to state that in your business case.

If there are any alternatives, compare and contrast alternatives in your business case including any differences, advantages, and any associated (or extra) costs with each one. Be sure to use language and terminology that is applicable to your specific facility and industry. Consider working with both internal and external resources to gather information on any industry specific benchmarks; these could include what other companies are doing for training in your geographic region, as well as what resources could be available from your local community or technical colleges.

Finally, what’s the ROI? Including ROI information in your proposal for training is going to be key when presenting it to the decision makers. If the training can improve the safety of those performing the work or the surrounding environment, there should be no questions asked. Factors that contribute to your maintenance training ROI would be the added business benefits compared to the costs associated with the training. Don’t forget about the current resources within your own organization. Many companies have folks with years of experience that might be willing to help to impart that knowledge to others. Take advantage of those human resources before they are lost to retirement.

About the Author

Adrian Messer

CMRP, Vice President of Executive Services, Progressive Reliability

Adrian Messer has worked in the maintenance and reliability field for nearly 20 years. During that time, he has worked with manufacturing and distribution facilities across multiple industries helping to improve their plant’s asset reliability through improved condition monitoring. Adrian is Manager of US Operations at SDT Ultrasound Solutions. Previously he worked with Progressive Reliability to advise companies on reliability-focused contracting & hiring and to find M&R professionals for open jobs.

Adrian is a graduate of Clemson University with a Bachelor of Science in Management with a concentration in Human Resources. He is a Certified Maintenance and Reliability Professional (CMRP) through the Society for Maintenance and Reliability Professionals (SMRP) and is actively involved with SMRP on a local and National level. He resides in Anderson, South Carolina.