Building the manufacturing workforce one veteran at a time

Bill Leahy is the Chief Executive Officer at Renaissance Reliability, a veteran-owned and operated reliability and maintainability engineering consultancy dedicated to American manufacturers. Paul Lavoie is the Chief Manufacturing Officer at the State of Connecticut and is committed to helping manufacturers take advantage of market opportunities to grow their businesses and solidify Connecticut’s reputation as the Silicon Valley of advanced manufacturing.

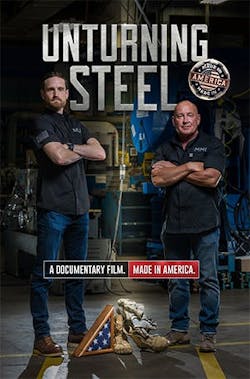

The two worked closely on Unturning Steel, a documentary that helps provide service members with a path forward after returning home. In the film, Bill sets out on a hero’s journey to help his fellow veterans bring their talents to American manufacturing. Together with the University of Tennessee-Knoxville, Bill has created a new offering that provides veterans the support and training they need to find purpose in American manufacturing.

Bill and Paul recently spoke with Plant Services editor in chief Thomas Wilk about their work with veterans and how their initiatives are helping to close the skills gap in manufacturing in North America.

Listen to Bill Leahy and Paul Lavoie on Great Question: A Manufacturing Podcast

PS: Paul, I understand you're instrumental in helping to identify the manufacturing and possibly academic partners within the states to further this process.

PL: Yeah, that's my job for Bill. My job is to get manufacturers engaged and get them to open their minds to taking a look at bringing our veterans on as part of their workforce. It can be a challenge with manufacturers who don't really think out-of-the-box when it comes to recruiting, and when it comes to building their teams. Quite frankly, you know we can't solve today's problems and tomorrow's problems with yesterday's solutions, and that's what we're trying to do.

My job is to is to enlighten our manufacturers to the opportunity that they have to build out a workforce. And what a better workforce! People always say “I'm looking for mid-level people.” Well, when you get a veteran, you're getting a mid-level person. You certainly don't need to teach them that they should show up. You certainly don't need to teach them to be on time. All of those things that they may struggle with somebody that’s first coming into the workforce – you don't need to teach them how to work, is my point. You just need to teach them the skills that they need, and that's a huge advantage. These folks come in and they go into maybe some entry level positions, but rapidly they become leaders in manufacturing facilities because of the skills that they gained in the military. So yeah, my job is to build the need and to get manufacturers engaged.

BL: Paul, you said two things and they just jumped to mind. The first one that caught my attention was when you were talking about your position, which is a government appointment – I did not understand that you were the only one in the country. You’re the only state with that, and I think it's brilliant, and this is why. Traveling around the country, working in all these different states and different manufacturers, the one thing I've noticed is, if I was going to say there was one big issue with U.S. manufacturing, I say it's resourcefulness. We have all the resources in the world. This the United States. This is Made in America. There is no shortage of resources for us.

It's about resourcefulness, and Paul, the position that you have and how you're helping me is exactly that. You're marshalling the resources for us and presenting them a way where they're accessible. And the rest of the country needs to follow suit. It's incredible! It's exactly what we need, we're setting the conditions for success in the state.

PL: You know, Bill, the way I look at it is, manufacturers are my customers, right? I was put in this role to serve my customers and I spend a large amount of my time listening to manufacturers and then linking them to the resources that they need to be successful. Yesterday I went to visit a company, and I had like seven referrals I needed to give to them on different things that they were looking for, and they we're just blown away. They're like. “the state does all of this stuff?” We actually have an Office of Manufacturing, my office has eight people in it. We have a manufacturing innovation fund which is money that we invest in the manufacturing sector. So I have program managers on that fund, and then I have three federal grants that we've received that come with durational position.

So we have this whole team that's looking to serve the manufacturing sector in three areas. It really is workforce development, supply chain resiliency, and innovation. You know, driving innovation in this sector as well, because we have to realize that we're never going to hire our way out of our workforce problem. There's never going to be enough people. And so, you know, while we'll exhaust in Connecticut all of the resources we can to get as many people as we can, then at the end of the day we have to drive innovation to get machines to do the work for people we're never going to have.

But that's right, that's the advantage. I think about this stuff all day, every day, and we're the only state that has somebody like this that's thinking about this all day, every day. We’re small enough that I can cover the entire state. I love my job. I have the best job in America.

BL: And incredible what it does for the state. This is something I will always talk about. There's resource availability, you're talking millions and millions and millions of dollars that just about every state is putting in, the federal government's throwing money at all of this, and that return on investment is only going to be realized if we have the appropriate implementers in place.

When you talk about mid-level people coming in, those are implementers. They have the skills, the knowledge, the ability, all of those things to actually take these resources and maximize them, put them to use. I cannot tell you the number of factories that I go to that has tech launched everywhere and they're collecting all kinds of data, but no one's doing anything with it. We need to create these implementers. And yes, with innovation, we can reduce the need for 100 operators lined up on something. But even with that, if we do not have the people to manage the innovations, the technology, and the operation, it’s for naught.

PS: As you both said, there's a pipeline of workers who are ready to work, and they know how to work and know how to show up. And for a sector of industry which often tries to hire in at the journeyman level or close to it, you've got people who have some of those skills coming out of the military. It’s a ready-made, leveled-up skill set that’s become available now to industry.

PL: Yeah, and they know how to learn. Teaching them new skills for them, that's all-day every-day in the military. So you bring them into a manufacturing setting, you have a senior level person that's ready to learn. And as they bring on technologies they have an opportunity just to be a natural fit for them to slide into those roles.

PS: Before we shift over to talking about the panel coming up at the Marcon conference that showcases some of what Unturning Steel has been doing, Bill, you mentioned there were some opportunities possibly in the works, some concrete opportunities and possibly leveraging federal programs like the CHIPS Act. Can you tell us something about that?

BL: Yeah, I'd be happy to. I met a couple of great ladies from all the connections that Paul's put me in touch with, and these are two ladies out in New Haven and they've identified an opportunity within the CHIPS Act. They recognize the defense industry that's present in the State of Connecticut and the need for their services. So they are starting a microchip company from scratch, essentially, and setting it up. These ladies are entrepreneurs. They're brilliant, but as far as manufacturing goes, they don't have that experience, so they've reached out to us. It’s a really cool opportunity, and I hope it works out. They have a completely blank roster at this point in time, and this could be an opportunity for us to really put our program to the test and see if we could fill out an entire company floor with our veterans, trained to our standard under the University of Tennessee and I would love to see that happen. I'll probably film that too and put that out there, but that would be incredible. They're doing some great work. It’s a minority female owned business, and I think they've got the chops to make it happen and I can't wait to see what happens with that. So that's within the State of Connecticut.

What we're setting up right now is I'm talking with veterans every single day. There's people reaching out just organically asking about the program and when it's going to be happening and where. The talent level – I wanted to mention this, the candidates that we are receiving – are incredible. If I had positions for all of them, I'd probably hire them all myself. They're just fantastic people, they're eager to learn and ready to get in and get started. So the State of Connecticut's going to do very well with bringing veterans back home and keeping the ones that we have stationed here.

On the state side, it gives us the opportunity to make our services accessible to organizations that would never even hear of this stuff before. On the big scale nationwide, we're looking for some big time corporate partners that want to really develop a reliability culture across their organization. The way we do that is by establishing a standard that's universally understood, and one of the companies that we're currently working with is Weyerhauser. They have sawmills and different facilities all across the country with about 200 people in each one. And they've been training with us for some time and they have certified Reliability & Maintainability Implementation Certification holders that are there on staff, and they're going to serve as our coaches going forward.

So when the veterans come, they train with us and then we send them out to go discover their future. They will be working with people that have done it before who will help them with their project work. That's the community piece that we're talking about. But within that, now we have an entire company talking the same manufacturing, the same reliability language. They have the same tools, artifacts, all of that stuff to build a culture, and they're going to realize great benefits from it. If you're competing out there or if you want to take out the competition and get yourself a differentiator or competitive advantage, Unturning Steel is one avenue towards that.

PS: Let's close out our conversation by talking about what people who are coming to Marcon in about a month can expect. This episode will go live probably about two weeks before the event, but a bunch of us are going to convene down in Knoxville, TN the week of March 4th to showcase some elements of this program.

BL: Yes, we are, we've got two screenings at Marcon. I just want to say the University of Tennessee has been absolutely fantastic. They've been on the cutting edge of the manufacturing education space for a long time, and I think they're in a position to really grow their presence, their mission and everything like that. So they're fantastic.

There's a lot of exciting things going on with the conference, but the most exciting is on March 6. Two things are happening for us, and I'm going to brag about us for a little bit, but the morning of the 6th we're getting the best Cultural Innovation award from the University of Tennessee, and we are so excited and grateful for that. And that evening, we are going to present the film for the first time, the inaugural screening of it as part of the conference. So I'll do an intro of about 20 minutes to say thank you to everybody, we'll screen the 22-minute first episode of our docu-series and then we'll go into that panel discussion afterwards. We've got some great folks on that, including Lisa Brownlee, she's a leadership expert working in the manufacturing space. Also going to be there is Blake, one of our students from this summer, so we have an Army graduate, an Unturning Steel graduate, a Navy veteran and a bunch of others that are really going to enlighten us. And you, Sir, are our moderator.

PS: I am! I will be there. I can't wait to see the film and get to meet all the people who were involved. Just talking with you and Paul today has me all fired up about this once again, so thank you for the opportunity to work together.

BL: We’ve got to get Paul down to Knoxville, too. We'll put up an extra chair on the panel for you!

PS: Thank you both for being here for the conversation today, Bill and Paul, for being part of this program. And I'm going to put all the links to relevant information both to your office, Paul, in the podcast notes and information about Unturning Steel and the panel coming up. So thank you for being in this episode, hope to talk to you both again real soon.

PL: Thank you for giving us the opportunity to amplify Bill’s work, but to also to provide great manufacturing jobs for our military veterans. Manufacturing jobs, change lives, and so we're excited about the project that we're working on.

BL: That's well said, thank you so much. Manufacturing saved my life. I was getting out of the service 100% dead, and I want to recreate that magic for some other deserving veterans.