Strategic planning: Is your plant headed in the right direction?

Road trips were always a favorite of my family. My children still recall favorite family moments from our numerous car trips throughout the United States. Planning is key to a good road trip, as jumping in a car with no plan with three energetic kids is not my idea of a good time. Our road trip plans focused on seeing national parks that were close together to minimize driving time. Hotels were always arranged ahead of time, and there were contingencies for weather, closures, detours, and caring for First Aid cases.

The analogy of planned road trips to the maintenance and reliability activities of many manufacturing facilities is not a stretch. Many manufacturing facilities basically jump into equipment care tasks without a plan delineating which tasks are most important, which equipment needs speedy attention, how the care satisfies the business’s needs, and how to move toward more proactive tasks and away from the “detours” of reactive work. Creating a safer workplace, achieving fewer failures, improving equipment uptime, and reducing maintenance costs is a journey of a few years. Every facility needs a map – a strategic plan – so as not to get lost.

Creating a strategic plan for maintenance and reliability (M&R) involves a unique set of activities within the asset care field. The essence of strategic positioning is to prioritize activities in the M&R field. Strategic planning is all about aligning M&R activities with the needs of your business.

Strategic planning basics

Strategic planning prepares to guide the facility for two to three years. It is different in purpose from tactical or operational planning, which have shorter time horizons. The strategic plan directs the facility on how it will approach the various areas of M&R to “fit” with the needs of the business.

[sidebar id="5"]

For example, if a manufacturing site is producing a commodity product where margins are tight and market share is won and lost over a few cents per pound, then the maintenance approach will be directed more toward the lowest-cost care options, such as the use of contract maintenance/contract services, expanded use of technology, and reliance on benchmarks for evaluating performance. If a facility is sold out but enjoys a lucrative margin in the marketplace, its approach to maintenance and reliability will focus more on the use of in-house resources and wider use of reliability practices and consultants. The decisions all are based on the input and outputs to and from the strategic planning process.

The process begins with gathering information on the business’s current situation – its position in the marketplace, its place in the industry, its customers’ demands, etc. An assessment of the facility’s care for its assets and the performance of its assets will be needed inputs.

A strength, weakness, opportunity, and threats (SWOT) analysis is then populated to understand the internal and external impacts on the facility. This analysis includes strategic questioning of how equipment strategies are created and executed, how effective those executing care are, how reliability gets built into new capital projects, and the status of the operations, maintenance, and engineering partnership.

The analysis looks at combinations of opportunities versus strengths and weaknesses and threats versus strengths and weaknesses. The conclusions from these comparisons generate the strategies, which provide an overall direction to aligning asset care with business needs.

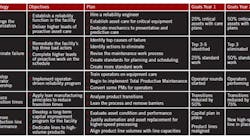

Once the strategic focus areas are formed, each is broken down into objectives that will provide measurable outcomes. Plans are generated that represent the improvement path projects needed to meet stated objectives. Then, milestones or goals along the improvement path are generated, challenging the organization to perform at higher levels. The entire “package” must then be sold to all stakeholder groups – investors, leadership, community, and facility personnel.

Case study example

The fictional Ruff Manufacturing plant produces pet-food solutions in various sizes of packaging. The Ruff facility contains food processing equipment (silos, mixers, grinders, and ovens), packaging equipment (sterilizers, box makers, box and bag fillers, palletizers, conveyers, and stackers), and utility systems (compressed air, steam, water). The facility has four production lines and six packaging lines for cans, boxes, and bags. The operation runs 24 hours a day, 7 days a week. Housekeeping and safety performance are below industry norms.

The maintenance organization has eight multicraft mechanics in production and 10 multicraft mechanics in packaging on a 12-hour day shift. A smaller crew of four multicraft mechanics are in production, and six multicraft mechanics are on the second 12-hour shift. A weekend crew exists for coverage and is used for vacation relief. There are two supervisors on the day shift and one supervisor on the second 12-hour shift. The weekend crew reports to production supervision. Two planners, one for production and one for packaging, are on the day shift. Reporting to the maintenance manager are one maintenance engineer and one packaging engineer.

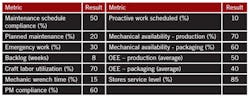

The maintenance strategy has been based on OEM recommendations for care, focusing on PMs for the majority of care tasks. The maintenance work is mainly reacting to equipment failure and executing PMs (see Table 1). There are no predictive maintenance tasks. Operators do not take an active role in providing care for the equipment and are accustomed to running equipment until it fails. Most operators learn on the job how to run the equipment, which is not highly automated.

1. Collect information

The company’s goal is to expand product offerings and create more “boutique” pet-food blends to meet consumer demand for choices made with natural and wholesome ingredients. Just-in-time order fulfillment patterns from distributors is another growing trend for this industry.

The facility is struggling with expanding production to meet the company’s strategy, though. The lack of capacity in both production and packaging leaves no time for new product lines. The company will sometimes toll-manufacture some product lines to meet demands. Orders are often delayed when meeting demands from distributors for just-in-time orders. Equipment breakdown and long transition times between products further contribute to delays. The company estimates that it needs a 30% increase in OEE across the facility to meet its production goals.

2. Perform SWOT analysis

A recently performed SWOT analysis indicated that the key strategic issues for Ruff manufacturing are: 1) How can the business improve OEE to expand its product lines and take back the toll manufacturing? 2) How can the company reduce failures to improve mechanical availability? 3) How can Ruff improve its operating culture to reduce failures and improve transition times? 4) How can the company use lean manufacturing and automation to boost productivity? 5) How can organizational changes improve the company’s manufacturing and maintenance execution performance?

3. Define strategies

The following is a subset of the strategies aimed at improving OEE, generated from comparing Ruff’s opportunities with its weaknesses:

- Structure Ruff Manufacturing to have reliability responsibilities to create and modify equipment care strategies and maintenance responsibilities to execute equipment care and restorative tasks.

- Eliminate failure by fixing the top causes of equipment breakdown and executing higher levels of planned and proactive asset care tasks.

- Develop a culture of operator ownership of assets to improve safety, housekeeping, and equipment performance.

- Reduce transition times between product changeovers to improve OEE through lean manufacturing application.

- Align production line performance with product demands through production planning, automation, and capital improvements.

4. Set objectives, goals, and plans

The strategic plan represents the answer to what needs to be done to improve OEE for the manufacturing organization. This guidance should represent a path for several years with targets set along the way to reach the desired 30% increase in OEE. The next level of the strategic plan represents the “how” through objectives, goals, and plans (see Table 2).

5. Gain approval

Once the entire plan is put together, all stakeholders in the organization must approve it. This is a top-down approach that focuses first on investors and the company’s leadership. In some cases, capital owned by these stakeholders is needed to execute plan objectives. Approval from key players will lead other stakeholders to perceive that management supports this initiative, which is vital to remaining stakeholders’ buy-in. The strategic plan provides a view to the company’s future; this may reduce the risk of losing vital talent.

Strategic planning is used to set priorities and focus energy and resources, align the needs of operations with those of the business, and ensure that employees and other stakeholders are working toward common goals. Many times the organization needs to assess and adjust the organization’s direction in response to a changing business environment. The path provides guidance for years and shapes what an organization is, whom it serves, what it does, and why it does it.